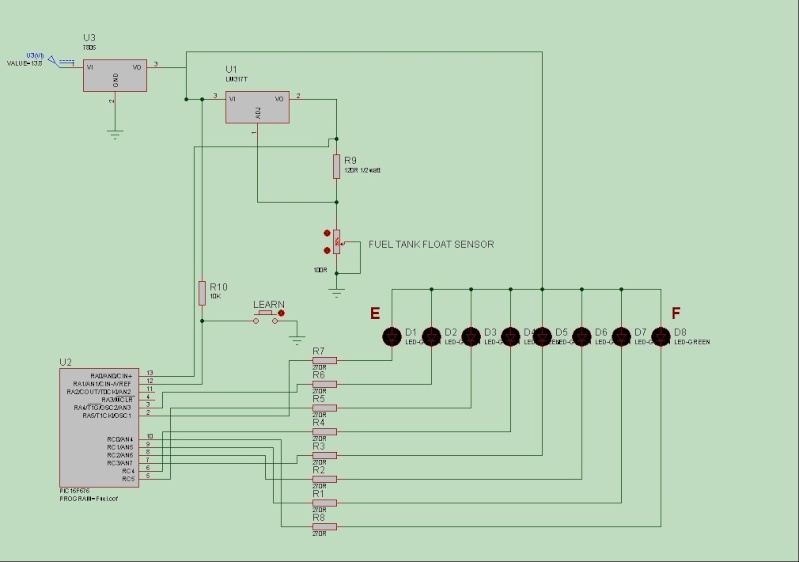

Circuit diagram.....

ASM code for the PIC 16F676.......

Code: Select all

; My Motorcycle fuel guage.

; The Honda has a 0-100 Ohm wirewound float sensor in post 2001 models, many pre '01 model owners have

; fitted the larger 19 litre tanks and dont have a fuel guage in the instrument cluster.

; I'm going to fit a VFR sensor to my 16 litre tank and have designed this simple circuit and code to display

; the fuel level on 8 leds, 1 led for each 2 litres of fuel.

; The circuit works as follows...

; Ign voltage is regulated by a LM7805 regulator, the output 5 volts is used for the PIC supply and also feed

; into a LM317T to limit the voltage and current being sent into the petrol tank, high voltage and current

; produces sparks and you definately dont want that!!

; The current is limited to 10mA and the voltage through the sensor changes from approx. 1.25V when empty to 2.5V

; when full this voltage is feed into an Analog to Digital convertor within the PIC and converted to a digital number.

; In the mainloop 10 readings are taken with a .5 second pause between each and then averaged up to compensate

; for fuel level movement during riding.

;

; The number of samples taken and delays are easily changed within the code if unstable readings due to movement

; are displayed.

;

; How to set-up for first use.

; Unfortunately you will have to completely drain the tank and have enough fuel available to fill it up.

; With an empty tank and the bike perfectly level, power on the unit with the button held down for at least a second,

; release the button for 1 sec and depress again for 1 sec. this sets the very empty setting, you can add fuel beforehand

; but not enough to raise the float.

; When the button is released the first led will flash slowly, measure out the fuel and add to the tank.

; When the level has stabilised and the float has moved, depress the button for 1 sec, the led will flash rapidly

; to indicate that the setting for that level has been set.

; Release the button and then the second led will flash slowly, add fuel and repeat the procedure until finished. the last

; led will not need to be set as anything above led no:7 will indicate a full tank.

ERRORLEVEL -302 ;remove message about using proper bank

processor 16F676

#include <p16F676.inc>

__config _CPD_OFF & _CP_OFF & _BODEN & _MCLRE_OFF & _PWRTE_ON & _WDT_OFF & _INTRC_OSC_NOCLKOUT

;**********************************************************************************************************

;***** Declaration of variable *****

cblock 0x20

Disp

temp

temp2

LED

NUMLEDS

THRESH1

THRESH2

THRESH3

THRESH4

THRESH5

THRESH6

THRESH7

THRESH8

PAUSEL

PAUSEH

ADCCount

ADC_Res0

ADC_Res1

AA0

AA1

AA2

BB0

BB1

REMB0

REMB1

Loopcount

endc

;**********************************************************************************************************

;***** Declaration of symbol equates *****

LEARNBTN equ 1 ; PORTA, pin RA1, has the "Learn" mode pushbutton

;**********************************************************************************************************

;***** Beginning of program memory structure *****

org 0x00

;**********************************************************************************************************

Start:

bsf STATUS,RP0 ; select Register Page 1

movlw 0x03

movwf TRISA ; Make PortA all ouput except RA0/1

clrf TRISC ; Make PortC all output

movlw 0x50 ; A2D Clock Fosc/16

movwf ADCON1

movlw 0x01 ; All Port A pins digital, except RA0

movwf ANSEL

bcf STATUS,RP0 ; address Register Page 0

movlw 0x07 ; Comparators off

movwf CMCON

movlw B'00000001'

movwf ADCON0 ; configure A2D for Channel 0 (RA0), Left justified, and turn on the A2D module

clrf ADRESH

movlw 0x7F ; Display off

movwf PORTC

bsf PORTA,4

bsf PORTA,5

movlw 0x08

movwf NUMLEDS

movlw 0x08

movwf LED

;**********************************************************************************************************

; Test to see if we should go into "Learn" mode.

; The PORTA RA1 pin has a pushbutton. Holding the button down at power on will cause the pin to go low

; and enter the learning routines.

checklearn

btfsc PORTA,LEARNBTN ; Check if the push button is being held down

goto LoadEE ; If not, then proceed

movlw high .1000 ; If so, then setup to debounce for 1 sec (1000 ms)

movwf PAUSEH

movlw low .1000

movwf PAUSEL

call Pausems

btfsc PORTA,LEARNBTN ; And check if the button is still being held down

goto LoadEE ; If not, then proceed

;**********************************************************************************************************

; Here we cycle through the LEDS 1 by one to learn the ADC threshold per 2 litres of fuel

; to the fuel tank. BUT the empty setting needs to be set first, no leds will be on for this

Startlearn

btfss PORTA,LEARNBTN ; Wait for the button to be released

goto $-1 ; Loop until button released

;**********************************************************************************************************

BlinkSlow

movlw high Hextoled

movwf PCLATH

movfw LED ; Get the LED number to be displayed

call Hextoled ; Convert it

movwf Disp

movwf temp2

comf Disp,1

movfw Disp

movwf PORTC ; Turn off the PORTC pins

movfw temp2 ; Ports only have 6 bits, get bits 7&8

andlw B'11000000' ; and use for PORTA.

movwf temp

rrf temp,1

rrf temp,1

comf temp,1

movfw temp

movwf PORTA

movlw high .500 ; Pause for 500 ms

movwf PAUSEH

movlw low .500

movwf PAUSEL

call Pausems

btfss PORTA,LEARNBTN ; Check if button pressed

goto Learn ; If so, proceed to learn it

movlw 0x7F ; Otherwise, turn off all leds

movwf PORTC

bsf PORTA,4

bsf PORTA,5

movlw high .500 ; Pause for 500 ms

movwf PAUSEH

movlw low .500

movwf PAUSEL

call Pausems

goto BlinkSlow ; Continue to flash the display

;**********************************************************************************************************

; Learn the actual ADC Reading for the gauge

Learn

movlw high .100 ; Debounce the pushbutton. Pause for 100 ms

movwf PAUSEH

movlw low .100

movwf PAUSEL

call Pausems

btfsc PORTA,LEARNBTN ; Check if button is still depressed

goto BlinkSlow ; If not, then resume flashing

BSF ADCON0,GO

BTFSC ADCON0,GO_DONE

GOTO $-1

MOVF ADRESH,W

movwf temp2

call WriteEE ; Store the ADC value into EEPROM

;**********************************************************************************************************

; Indicate that "Learning" has completed, by flashing the LEDs on/off quickly (once every 400 ms).

; We'll do this until the user releases the pushbutton.

BlinkFast

movlw high Hextoled

movwf PCLATH

movfw LED ; Get the LED number to be displayed

call Hextoled ; Convert it

movwf Disp

movwf temp2

comf Disp,1

movfw Disp

movwf PORTC ; Turn off the PORTC pins

movfw temp2 ; Ports only have 6 bits, get bits 7&8

andlw B'11000000' ; and use for PORTA.

movwf temp

rrf temp,1

rrf temp,1

comf temp,1

movfw temp

movwf PORTA

movlw high .200 ; Pause for 200 ms

movwf PAUSEH

movlw low .200

movwf PAUSEL

call Pausems

btfsc PORTA,LEARNBTN ; Check if button pressed

goto LearnNext ; If not, proceed to set up for learning the next threshold

movlw 0x7F ; Otherwise, turn off all leds

movwf PORTC

bsf PORTA,4

bsf PORTA,5

movlw high .200 ; Pause for 200 ms

movwf PAUSEH

movlw low .200

movwf PAUSEL

call Pausems

goto BlinkFast ; Then continue flashing the display quickly

;**********************************************************************************************************

; Now that we've "Learned" a setting, and the user has released the pushbutton, set up for learning

; the next led.

LearnNext

movlw high .100 ; Debounce the pushbutton. Pause for 100 ms

movwf PAUSEH

movlw low .100

movwf PAUSEL

call Pausems

btfss PORTA,LEARNBTN ; Check if button is still released

goto BlinkFast ; If not, then resume flashing

decf LED,F ; Decrement the led number to be learned

decfsz NUMLEDS,F ; Decrement the learning loop counter, and exit if zero

goto BlinkSlow ; Got it,start blinking the new led we need to learn

goto LoadEE ; Whewww, we're done

;**********************************************************************************************************

; Here we retrieve all previously "Learned" data from EEPROM.

LoadEE

call LEDCheck

movlw 0x08

movwf LED ; Re-hydrate all the RAM variables used to hold the thresholds

call ReadEE ; Working from LED 8 thru 1

movwf THRESH8

decf LED,F

call ReadEE

movwf THRESH7

decf LED,F

call ReadEE

movwf THRESH6

decf LED,F

call ReadEE

movwf THRESH5

decf LED,F

call ReadEE

movwf THRESH4

decf LED,F

call ReadEE

movwf THRESH3

decf LED,F

call ReadEE

movwf THRESH2

decf LED,F

call ReadEE

movwf THRESH1

;**********************************************************************************************************

; Due to the delays in the mainloop it can take a few seconds for the display to show anything, therefore

; we take a quick reading to start with.

firstreading

BSF ADCON0,GO

BTFSC ADCON0,GO_DONE

GOTO $-1

MOVF ADRESH,W

goto Gauge

;**********************************************************************************************************

MainLoop:

CLRF ADC_Res1

CLRF ADC_Res0

CLRF ADCCount

;**********************************************************************************************************

; Here we take 10 ADC readings with a 500ms delay between each sample, each sample is added to the previous

; one.

ADCLoop

MOVF ADCCount,W

SUBLW .9 ; Have we taken 10 samples?

BTFSS STATUS,C

GOTO ADCAverage ; Yes then now get the average

BSF ADCON0,GO

BTFSC ADCON0,GO_DONE

GOTO $-1

MOVF ADRESH,W

ADDWF ADC_Res0,F

BTFSC STATUS,C

INCFSZ ADC_Res1,F

INCF ADCCount,F

movlw high .500

movwf PAUSEH

movlw low .500

movwf PAUSEL

call Pausems

GOTO ADCLoop

;**********************************************************************************************************

; All 10 samples have been taken, grab the total and divide the result by 10.

ADCAverage

movfw ADC_Res0

movwf AA2

movfw ADC_Res1

movwf AA1

clrf AA0

clrf BB0

movlw .10

movwf BB1

Call DIV24x16

movfw AA2

;**********************************************************************************************************

; Here we take the average reading and compare it to the threshold values learned from the set-up routines.

; The average value is loaded into the W reg and the threshold value is subtracted, the Carry bit will be set

; if the threshold value is greater than the average reading.

Gauge

movwf temp2

movlw 0x08

movwf LED

movfw temp2

subwf THRESH8,W ; If W > THRESH, then C will be clear

btfsc STATUS,C ; If C is clear, then move on

goto EDisplay

decf LED,F ; Next led

movfw temp2

subwf THRESH7,W ; If W > THRESH, then C will be clear

btfsc STATUS,C ; If C is clear, then move on

goto FDisplay

decf LED,F ;

movfw temp2

subwf THRESH6,W ; If W > THRESH, then C will be clear

btfsc STATUS,C ; If C is clear, then move on

goto Display

decf LED,F ;

movfw temp2

subwf THRESH5,W ; If W > THRESH, then C will be clear

btfsc STATUS,C ; If C is clear, then move on

goto Display

decf LED,F ;

movfw temp2

subwf THRESH4,W ; If W > THRESH, then C will be clear

btfsc STATUS,C ; If C is clear, then move on

goto Display

decf LED,F ;

movfw temp2

subwf THRESH3,W ; If W > THRESH, then C will be clear

btfsc STATUS,C ; If C is clear, then move on

goto Display

decf LED,F ;

movfw temp2

subwf THRESH2,W ; If W > THRESH, then C will be clear

btfsc STATUS,C ; If C is clear, then move on

goto Display

decf LED,F ;

movfw temp2

subwf THRESH1,W ; If W > THRESH, then C will be clear

btfsc STATUS,C ; If C is clear, then move on

goto Display

decf LED,F ; then we must have a full tank!!!

goto Display

;**********************************************************************************************************

; Take the led number where the carry bit was set and lookup the result to switch the port bits on or off

Display

movlw high Hextoled

movwf PCLATH

movfw LED ; Get the number of LED's into the W register

call Hextoled ; Convert it

movwf Disp

movwf temp2

comf Disp,1

movfw Disp

movwf PORTC ; Turn off the PORTC pins to ground

movfw temp2 ; Ports only have 6 bits, get bits 7&8

andlw B'11000000' ; and use for PORTA.

movwf temp

rrf temp,1

rrf temp,1

comf temp,1

movfw temp

movwf PORTA

goto MainLoop

;**********************************************************************************************************

EDisplay ; Flashes all leds as tank is very empty!!

movlw .5

movwf temp

Empty

movlw 0x00 ; turn on all leds

movwf PORTC

bcf PORTA,4

bcf PORTA,5

movlw high .200 ; Pause for 200 ms

movwf PAUSEH

movlw low .200

movwf PAUSEL

call Pausems

movlw 0x7F ; turn off all leds

movwf PORTC

bsf PORTA,4

bsf PORTA,5

movlw high .200 ; Pause for 200 ms

movwf PAUSEH

movlw low .200

movwf PAUSEL

call Pausems

decfsz temp,f

goto Empty

goto MainLoop

;**********************************************************************************************************

FDisplay ; Flashes first led as warning

movlw .5

movwf temp

LowF

movlw 0x7F ; turn on first led

movwf PORTC

bsf PORTA,4

bcf PORTA,5

movlw high .500 ; Pause for 200 ms

movwf PAUSEH

movlw low .500

movwf PAUSEL

call Pausems

movlw 0x7F ; turn off all leds

movwf PORTC

bsf PORTA,4

bsf PORTA,5

movlw high .500 ; Pause for 200 ms

movwf PAUSEH

movlw low .500

movwf PAUSEL

call Pausems

decfsz temp,f

goto LowF

goto MainLoop

;**********************************************************************************************************

; Subroutine: Pausems

; Used to burn some CPU cycles doing nothing meaningful.

; This routine assumes a system clock frequency of 4 MHz.

; Inputs:

; PAUSEL - Low order byte of the number of milliseconds

; PAUSEH - High order byte of the number of milliseconds

; Temporary:

; LOOPCOUNT - Loop counter

; Output:

; None

Pausems

Loop1

movf PAUSEL,F ; Decrease PAUSEH and PAUSEL the necessary

btfsc STATUS,Z ; number of times and call subprogram Delay1ms

goto Dechi

call Delay1ms

decf PAUSEL,F

goto Loop1

Dechi

movf PAUSEH,F

btfsc STATUS,Z

goto Done

call Delay1ms

decf PAUSEH,F

decf PAUSEL,F

goto Loop1

Delay1ms ; Delay1ms produces a one millisecond delay

movlw .100 ; 100*10us=1ms

movwf Loopcount ; LOOPCOUNT<-100

Loop2

nop

nop

nop

nop

nop

nop

nop

decfsz Loopcount,F ; Time period necessary to execute loop Loop2

goto Loop2 ; equals 10us

Done

return ; Return to caller

;**********************************************************************************************************

;Divide a 24 bit number by a 16 bit number, resulting in a 16 bit number

;Inputs:

; Dividend - AA0:AA1:AA2 (0 - most significant!)

; Divisor - BB0:BB1

;Temporary:

; Counter - LOOPCOUNT

; Remainder- REMB0:REMB1

;Output:

; Quotient - AA0:AA1:AA2

;

DIV24x16

clrf REMB0

clrf REMB1

movlw .24

movwf Loopcount

LOOPU2416

rlf AA2,W ;shift dividend left to move next bit to remainder

rlf AA1,F

rlf AA0,F

rlf REMB1,F ;shift carry (next dividend bit) into remainder

rlf REMB0,F

rlf AA2,F ;finish shifting the dividend and save carry in AA2.0,

;since remainder can be 17 bit long in some cases

;(e.g. 0x800000/0xFFFF). This bit will also serve

;as the next result bit.

movf BB1,W ;substract divisor from 16-bit remainder

subwf REMB1,F

movf BB0,W

btfss STATUS,C

incfsz BB0,W

subwf REMB0,F

;here we also need to take into account the 17th bit of remainder, which

;is in AA2.0. If we don't have a borrow after subtracting from lower

;16 bits of remainder, then there is no borrow regardless of 17th bit

;value. But, if we have the borrow, then that will depend on 17th bit

;value. If it is 1, then no final borrow will occur. If it is 0, borrow

;will occur. These values match the borrow flag polarity.

skpnc ;if no borrow after 16 bit subtraction

bsf AA2,0 ;then there is no borrow in result. Overwrite

;AA2.0 with 1 to indicate no borrow.

;if borrow did occur, AA2.0 already

;holds the final borrow value (0-borrow,

;1-no borrow)

btfsc AA2,0 ;if no borrow after 17-bit subtraction

goto UOK46LL ;skip remainder restoration.

addwf REMB0,F ;restore higher byte of remainder.

;(w contains the value subtracted from it previously)

movf BB1,W ;restore lower byte of remainder

addwf REMB1,F

UOK46LL

decfsz Loopcount,F ;decrement counter

goto LOOPU2416 ;and repeat the loop if not zero.

return

;**********************************************************************************************************

;**********************************************************************************************************

; Subroutine: WriteEE

; Write a byte of data to EEPROM storage

; Inputs:

; LED - should be set to the LED number, which will be used as the EEPROM address

; W register - should contain the data to be stored

; Temporary:

; None

; Output:

; None

WriteEE

banksel EEDATA ; Select the bank of EEDATA

movwf EEDATA ; Data value to write

banksel LED

movf LED,W ; Use the LED number as the EEPROM address

banksel EEADR ; Select bank of EEADR

movwf EEADR ; Data memory address to write

banksel EECON1 ; Select bank of EECON1

bsf EECON1,WREN ; Enable writes

banksel EECON2 ; Select bank of EECON2

movlw 0x55

movwf EECON2 ; Write 55h

movlw 0xAA

movwf EECON2 ; Write AAh

banksel EECON1

bsf EECON1,WR ; Set WR bit to begin write

btfsc EECON1,WR ; Wait for write to finish

goto $-1 ; looping until it is

bcf EECON1,WREN ; Disable writes

banksel 0 ; Select bank 0 now that we're all done

return ; Return to caller

; Subroutine: ReadEE

; Read a byte of data to EEPROM storage

; Inputs:

; LED - should be set to the LED number, which will be used as the EEPROM address

; Temporary:

; None

; Output:

; W register - contains the EEPROM data byte that has been read

ReadEE

banksel 0

movf LED,W ; Get LED number into the W register

banksel EEADR ; Select bank of EEADR

movwf EEADR ; Data memory address to read

banksel EECON1 ; Select bank of EECON1

bsf EECON1,RD ; EE Read

banksel EEDATA ; Select bank of EEDATA

movf EEDATA,W ; Get EEDATA into W register

banksel 0 ; Select bank 0 now that we're all done

return ; return to caller

;**********************************************************************************************************

; Just cycle through the leds in bar mode up and down to confirm all are working.

LEDCheck

bcf PORTA,5

movlw high .200

movwf PAUSEH

movlw low .200

movwf PAUSEL

call Pausems

bcf PORTA,4

movlw high .200

movwf PAUSEH

movlw low .200

movwf PAUSEL

call Pausems

bcf PORTC,5

movlw high .200

movwf PAUSEH

movlw low .200

movwf PAUSEL

call Pausems

bcf PORTC,4

movlw high .200

movwf PAUSEH

movlw low .200

movwf PAUSEL

call Pausems

bcf PORTC,3

movlw high .200

movwf PAUSEH

movlw low .200

movwf PAUSEL

call Pausems

bcf PORTC,2

movlw high .200

movwf PAUSEH

movlw low .200

movwf PAUSEL

call Pausems

bcf PORTC,1

movlw high .200

movwf PAUSEH

movlw low .200

movwf PAUSEL

call Pausems

bcf PORTC,0

movlw high .250

movwf PAUSEH

movlw low .250

movwf PAUSEL

call Pausems

bsf PORTC,0

movlw high .200

movwf PAUSEH

movlw low .200

movwf PAUSEL

call Pausems

bsf PORTC,1

movlw high .200

movwf PAUSEH

movlw low .200

movwf PAUSEL

call Pausems

bsf PORTC,2

movlw high .200

movwf PAUSEH

movlw low .200

movwf PAUSEL

call Pausems

bsf PORTC,3

movlw high .200

movwf PAUSEH

movlw low .200

movwf PAUSEL

call Pausems

bsf PORTC,4

movlw high .200

movwf PAUSEH

movlw low .200

movwf PAUSEL

call Pausems

bsf PORTC,5

movlw high .200

movwf PAUSEH

movlw low .200

movwf PAUSEL

call Pausems

bsf PORTA,4

movlw high .200

movwf PAUSEH

movlw low .200

movwf PAUSEL

call Pausems

bsf PORTA,5

movlw high .750

movwf PAUSEH

movlw low .750

movwf PAUSEL

call Pausems

return

;**********************************************************************************************************

; Table used for the display routine to switch bits on or off

Hextoled

; table in bar mode

addwf PCL,F

retlw 0xFF ;B'11111111' ;Full

retlw 0xFE ;B'11111110'

retlw 0xFC ;B'11111100'

retlw 0xF8 ;B'11111000'

retlw 0xF0 ;B'11110000'

retlw 0xE0 ;B'11100000'

retlw 0xC0 ;B'11000000'

retlw 0x80 ;B'10000000'

retlw 0x00 ;B'00000000' ;Empty

;**********************************************************************************************************

end