That's a great way to get urban camouflage on your bikeKev L wrote:Couple of good ideas there Al. Nice bit of stone cladding to give that classy overall look, nice bit of cast iron drain pipe to make up the oil lines and just to give it the final Coronation Street 2 up 2 down terrace look, a nice brick chimney, dual outlet, to replace the exhaust!AMCQ46 wrote:Have you thought about some ex Jack Duckworth stone cladding?

Clutch Cover Window with LED Lighting

Re: Clutch Cover Window with LED Lighting

You never see a motorcycle parked in front of a psychiatrists for psycho therapy. All I need is cycle therapy

Re: Clutch Cover Window with LED Lighting

BTW, that's called here Public Housing or AKA "Projects" as for the project of mixing low income families in high income communities which basically was a total failure IMO.

Back to the subject matter, Carl, don't get discouraged, they all jealous

Back to the subject matter, Carl, don't get discouraged, they all jealous

You never see a motorcycle parked in front of a psychiatrists for psycho therapy. All I need is cycle therapy

Re: Clutch Cover Window with LED Lighting

It makes no odds to me what people say. I am a free man and do as I like.  And if it's outside of the norm then all the better.

And if it's outside of the norm then all the better.  some may call that the mind of a genius

some may call that the mind of a genius

(:-})

(:-})

==============================Enter the Darkside

Re: Clutch Cover Window with LED Lighting

[youtube][/youtube]

It may be that your whole purpose in life is simply to serve as a warning to others.

VTR Firestorm and other bikes t-shirts

VTR Firestorm and other bikes t-shirts

VTR Firestorm and other bikes t-shirts

VTR Firestorm and other bikes t-shirtsRe: Clutch Cover Window with LED Lighting

Well that is different, but I may just end up with a fleet of windows.

(:-})

(:-})

==============================Enter the Darkside

Re: Clutch Cover Window with LED Lighting

and I thought you were a mac fan...

It may be that your whole purpose in life is simply to serve as a warning to others.

VTR Firestorm and other bikes t-shirts

VTR Firestorm and other bikes t-shirts

VTR Firestorm and other bikes t-shirts

VTR Firestorm and other bikes t-shirtsRe: Clutch Cover Window with LED Lighting

I like it.

(:-})

==============================Enter the Darkside

- agentpineapple

- Posts: 15124

- Joined: Sat Mar 26, 2011 9:16 pm

Re: Clutch Cover Window with LED Lighting

whats that then....an....iclutch......you might have trademark issues with that one......

HEY YOU GUYS!!!!!!

Re: Clutch Cover Window with LED Lighting

BrilliantWicky wrote:and I thought you were a mac fan...

You never see a motorcycle parked in front of a psychiatrists for psycho therapy. All I need is cycle therapy

-

whitestorm pete

- Posts: 362

- Joined: Tue Feb 07, 2012 8:47 pm

- Location: Market harborough Leicestershire

Re: Clutch Cover Window with LED Lighting

fair play to you mate its different and thats a good think aint it!

If sh1t were money you would be worth a fortune

Re: Clutch Cover Window with LED Lighting

Rock on Carl my man.cybercarl wrote:It makes no odds to me what people say. I am a free man and do as I like.And if it's outside of the norm then all the better.

some may call that the mind of a genius

(:-})

As the words from one of my fav songs says:

Just what is it that you want to do?

We wanna be free

We wanna be free to do what we wanna do

And we wanna get loaded

And we wanna have a good time

That's what we're gonna do

No way baby let's go

We're gonna have a good time

We're gonna have a party

Everything good is bad

Everything bad is good

Everything bad is good

Re: Clutch Cover Window with LED Lighting

All together as one, All together as one.

Primal Scream, Screamadelica great album.

(:-})

Primal Scream, Screamadelica great album.

(:-})

==============================Enter the Darkside

-

whitestorm pete

- Posts: 362

- Joined: Tue Feb 07, 2012 8:47 pm

- Location: Market harborough Leicestershire

Re: Clutch Cover Window with LED Lighting

great tune one of me favs

If sh1t were money you would be worth a fortune

- BigVeeGrin

- Posts: 2521

- Joined: Wed Feb 17, 2010 1:41 pm

- Location: Glasgow

Re: Clutch Cover Window with LED Lighting

and me - top, top album. I often sing this in my head when on the bike "we just wanna get loaded" then the crashing riff. ace

Re: Clutch Cover Window with LED Lighting

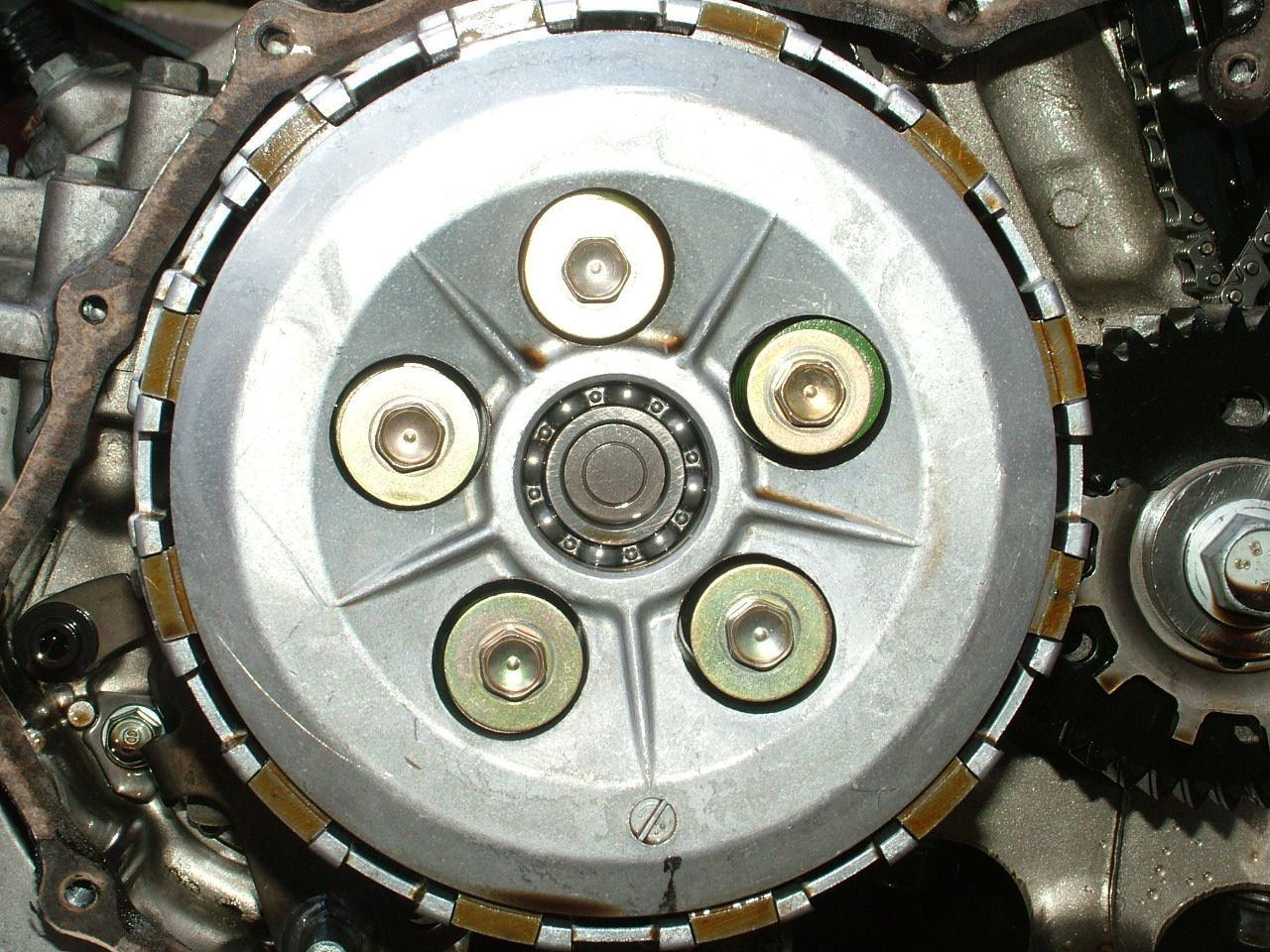

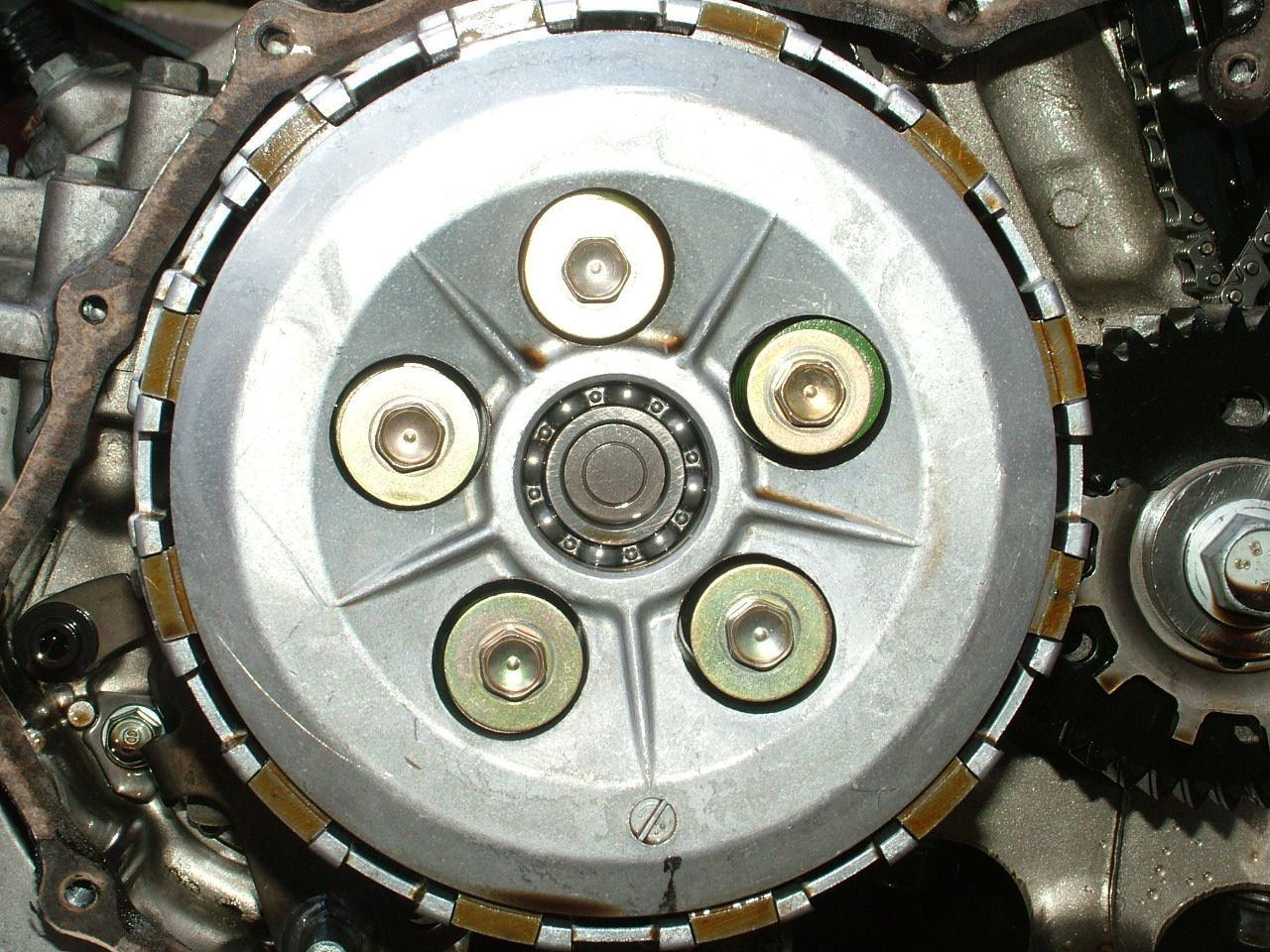

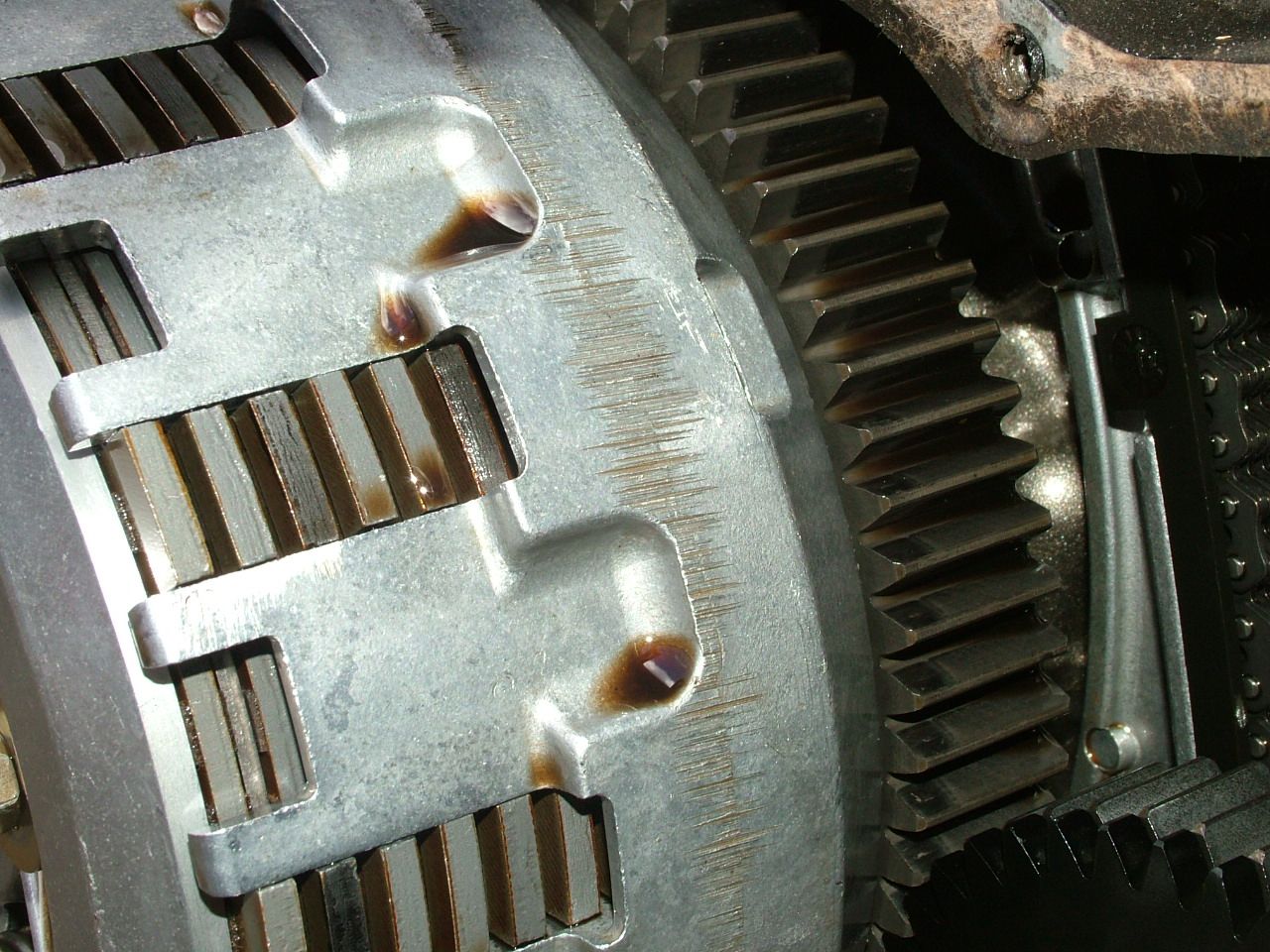

Done a bit more out in the cold today.

Removed the water pump and clutch casing off the bike.

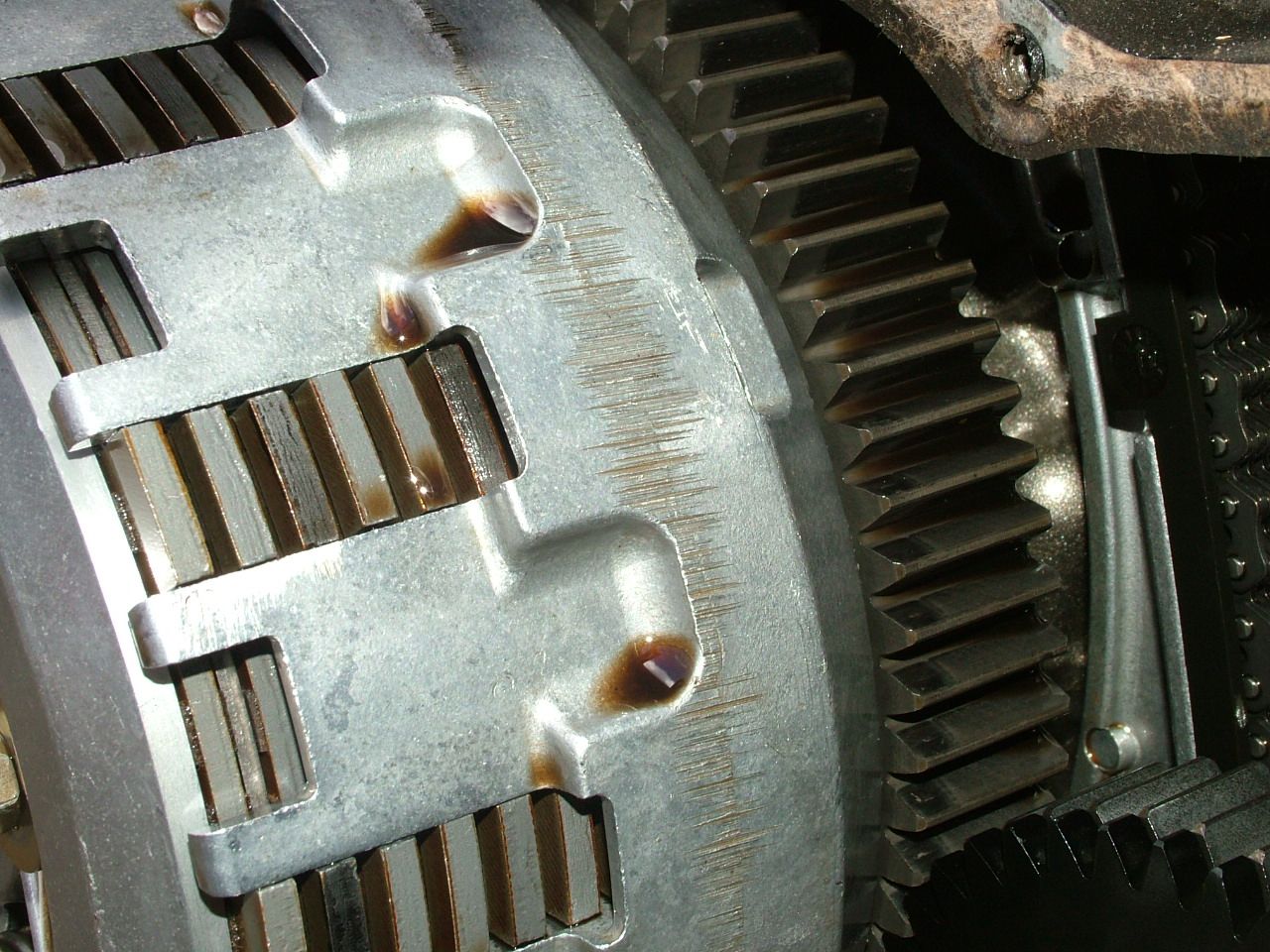

But noticed some wear marks around the outside edge of the clutch basket which is a bit concerning. I can also feel some furring on the inside of the cover where it has been rubbing.

The clutch basket feels nice and solid and there is no play (wobble) in it that I can feel, so what may be causing this.

The clutch basket feels nice and solid and there is no play (wobble) in it that I can feel, so what may be causing this.

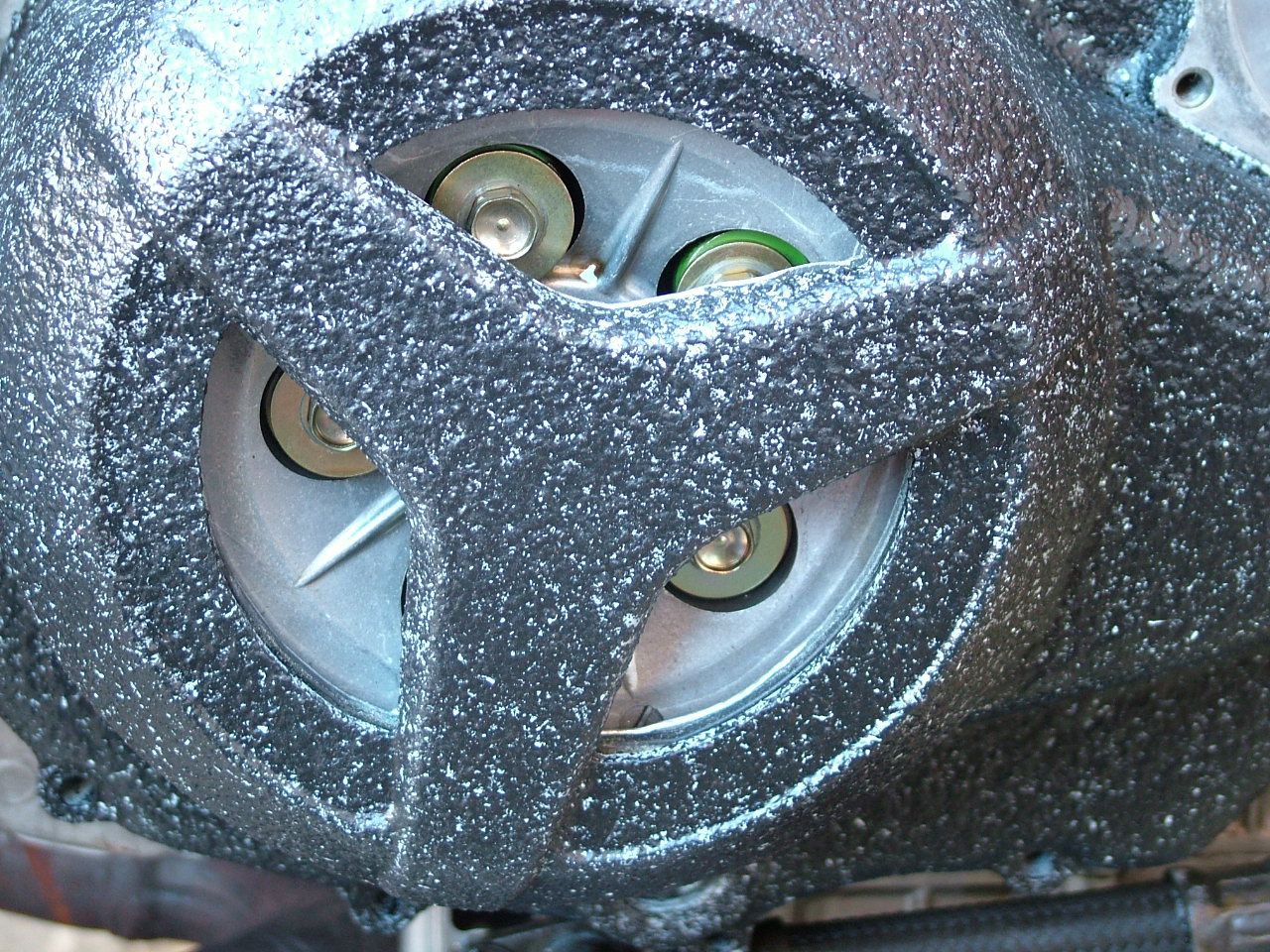

That's how tight tolerances are in there. So running wires for the LED along the inside of the casing towards the back is going to be out of the question. I may have to consider making a hole in the casing towards the outer part of the casing and running the wires along the outside of the casing which wont be as neat. Though I could spray over them so they blend in with the rest of it. Not ideal but LED's may still be possible if I run them as far towards the outer part of the casing as possible.

There is the slight angle on the outside of the pressure plate that leaves a bit of space. I will also have to grind some of the lips down on the inside of the case, just outside where the rubber seal sits, which will give me a bit more. I will have to wait until the LED's turn up and see how deep they are. I'm also thinking to run them around that part I will either have to cut splits every so often in the strip so it bends around or cut and splice some wires in the strip every so often. The LED strips can be cut every three LED's. A bit of an butt-ache and more work, but if needs be and it makes the job feasible, then so be it.

I'm also thinking to run them around that part I will either have to cut splits every so often in the strip so it bends around or cut and splice some wires in the strip every so often. The LED strips can be cut every three LED's. A bit of an butt-ache and more work, but if needs be and it makes the job feasible, then so be it.

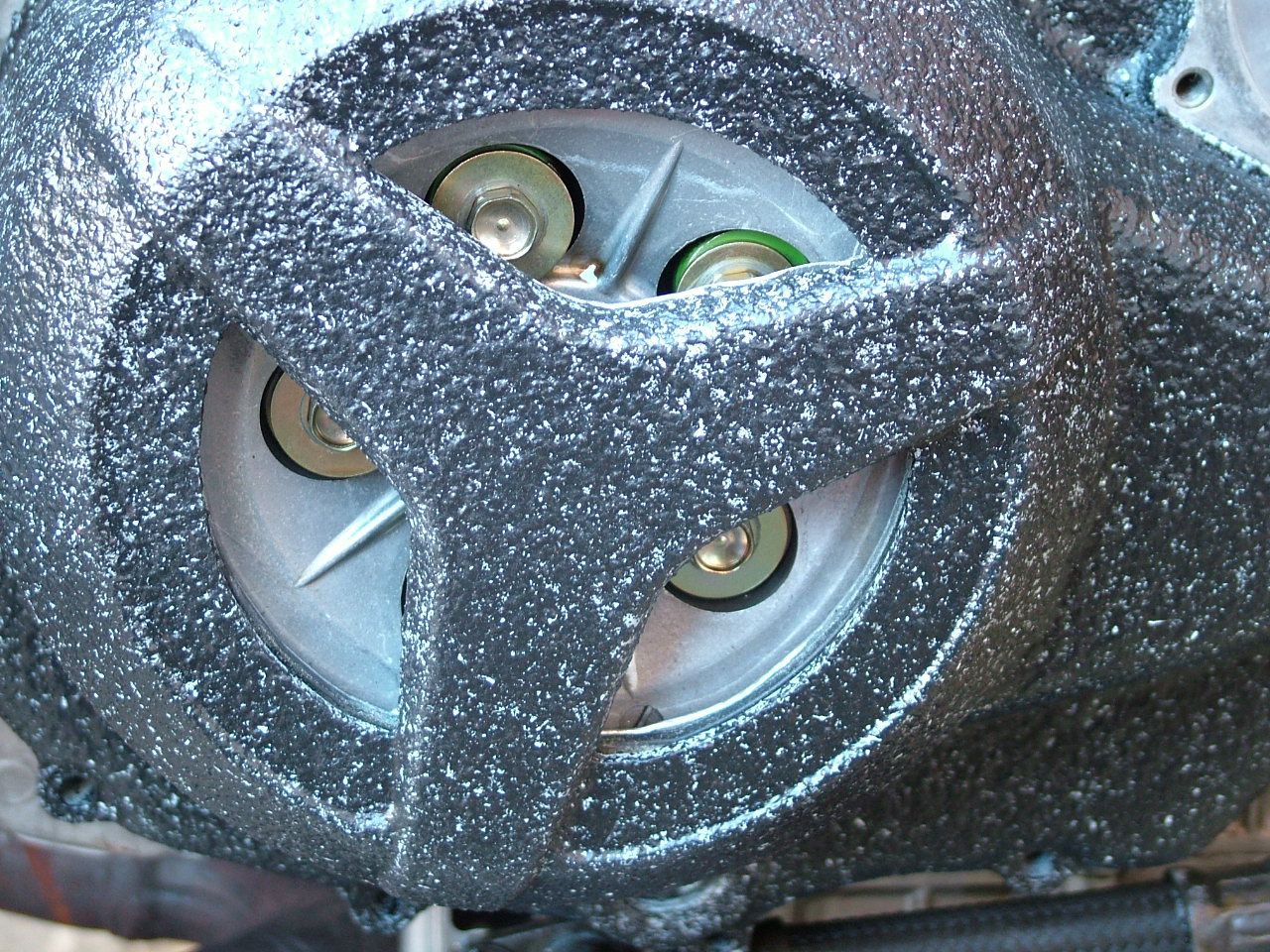

Put the new cover on to measure clearances for the window.

Yet again more tight clearances but window is not so much of a problem.

I tied my clutch lever back so the clutch was disengaged and I could measure maximum clearances which is 10mm without the rubber seal and quietening device from the outside point where I want the window to run flush like the original. This does not allow for any wear and tear on my clutch plates. I figured I should knock 1mm off to allow for a new clutch kit when it eventually needs it.

The rubber seal and quietening device are 4-5mm depending on how much the seal compresses down once everything is tightened up. So if we say 9mm clearance minus 5 to play on the safe side, that leaves me with fitting a 4mm Lexan window. The bit that protrudes through to make it flush with the front through my cut-outs is 2mm. So I'm looking at recessing part of the window by 2mm which leaves 4mm Lexan on the window areas and 2mm for the rest of it plus the quietening device.

That is probably the route I will take but 4mm Lexan is not much though it is tough stuff. My only other option would be to leave the quieting device off altogether and then I would have more clearance to add another couple of mm.

Why is everything I do such a challenge. Nothing is ever straight forward.

(:-})

Removed the water pump and clutch casing off the bike.

But noticed some wear marks around the outside edge of the clutch basket which is a bit concerning. I can also feel some furring on the inside of the cover where it has been rubbing.

That's how tight tolerances are in there. So running wires for the LED along the inside of the casing towards the back is going to be out of the question. I may have to consider making a hole in the casing towards the outer part of the casing and running the wires along the outside of the casing which wont be as neat. Though I could spray over them so they blend in with the rest of it. Not ideal but LED's may still be possible if I run them as far towards the outer part of the casing as possible.

There is the slight angle on the outside of the pressure plate that leaves a bit of space. I will also have to grind some of the lips down on the inside of the case, just outside where the rubber seal sits, which will give me a bit more. I will have to wait until the LED's turn up and see how deep they are.

Put the new cover on to measure clearances for the window.

Yet again more tight clearances but window is not so much of a problem.

I tied my clutch lever back so the clutch was disengaged and I could measure maximum clearances which is 10mm without the rubber seal and quietening device from the outside point where I want the window to run flush like the original. This does not allow for any wear and tear on my clutch plates. I figured I should knock 1mm off to allow for a new clutch kit when it eventually needs it.

The rubber seal and quietening device are 4-5mm depending on how much the seal compresses down once everything is tightened up. So if we say 9mm clearance minus 5 to play on the safe side, that leaves me with fitting a 4mm Lexan window. The bit that protrudes through to make it flush with the front through my cut-outs is 2mm. So I'm looking at recessing part of the window by 2mm which leaves 4mm Lexan on the window areas and 2mm for the rest of it plus the quietening device.

That is probably the route I will take but 4mm Lexan is not much though it is tough stuff. My only other option would be to leave the quieting device off altogether and then I would have more clearance to add another couple of mm.

Why is everything I do such a challenge. Nothing is ever straight forward.

(:-})

==============================Enter the Darkside