As we have the dyno day in June I'm just curious as to what set ups people are currently running and how its running for them

if you have a dyno sheet attach with your set up.

Copy the below and fill in with your data

My current settings

AIRBOX

MAIN - Standard

SNORKEL - Standard

LID - Flap removed

VELOCITY STACKS - Two Long Fitted

FILTER - Pipercross Race Filter

EXHAUST

PIPES - Yoshimura

CANS - Yoshimura

STYLE - Upswept

FRONT CARB

MAIN AIR JET DRILLED - No

MAIN - #190 Dyno Jet

EMULSION TUBE - Standard front

NEEDLES - Dyno Jet on 5th clip

SLIDES - Standard not drilled or blocked

SPRINGS - Standard

PILOT - #50

A/F SCREW - 2.25

REAR CARB

MAIN AIR JET DRILLED - No

MAIN - #190 Dyno Jet

EMULSION TUBE - Standard rear

NEEDLES - Dyno Jet on 5th clip

SLIDES - Standard not drilled or blocked

SPRINGS - Standard

PILOT - #50

A/F SCREW - 2.50

OTHER VARIABLES

TPS - 500 ohms

IGNITION ADVANCER - Standard

COILS - Stick Coil Conversion

GEARING - Standard

CLUTCH - EBC Kevlar Series Street Racing Clutch & Springs

FLYWHEEL - Standard

PISTONS - Standard

CAMS - Standard

OIL COOLER - Standard

ENGINE OIL - Castrol Power 1 10w/30 Semi Synthetic

OTHER -

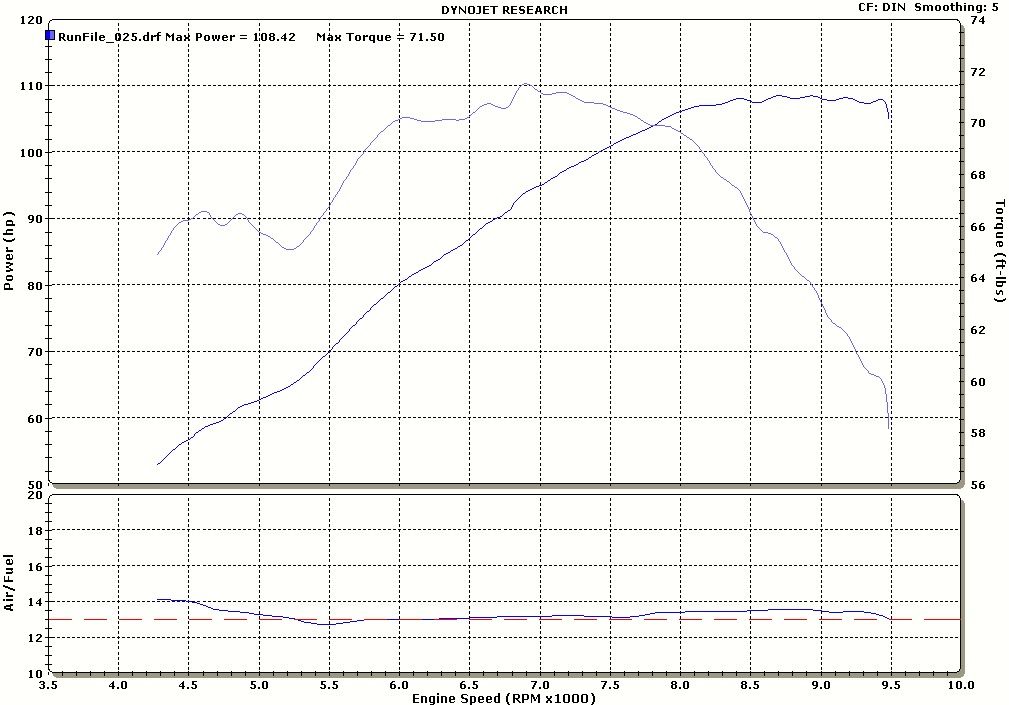

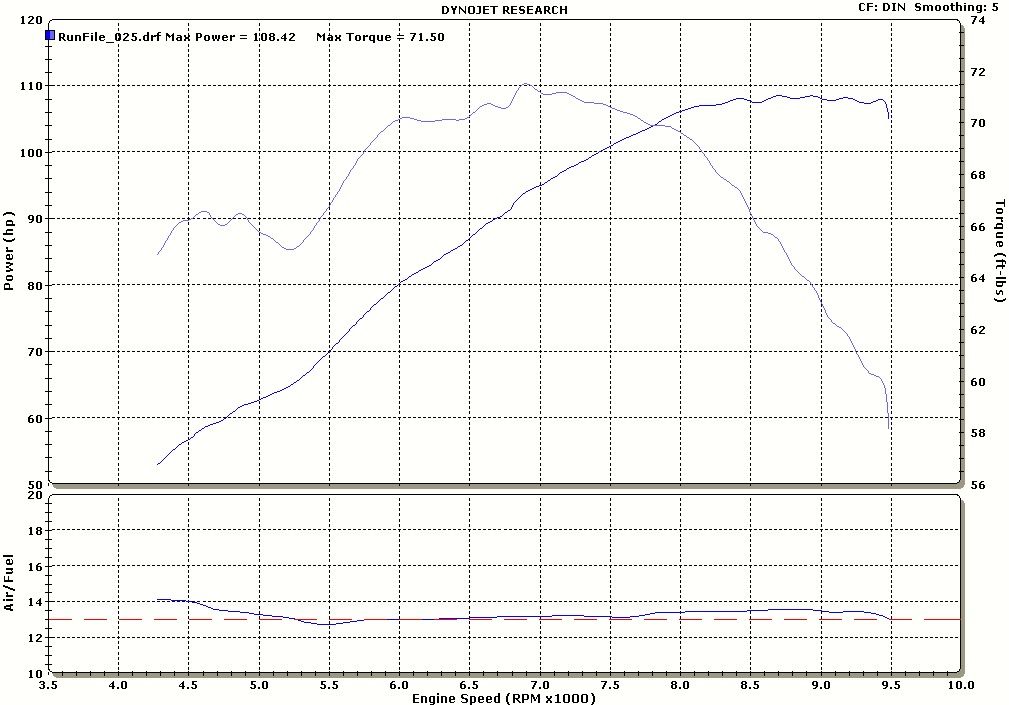

DYNO SHEET -

Bike rides very nice but feels ever so sightly lean around 5k ish

Power up top feels fantastic

Has a slight soggy feel just off idle if opened slow, tied with the #48's in but it caused big problems setting off it would hesitate and cut out for a millisecond, suspect the AF needs fine tuning when i can be arsed

Did have Lloydie Modified Air box fitted but damaged it on the weld so have to repair and get that back in and adjusted for it

What set up are you running, and how is it for you?

What set up are you running, and how is it for you?

Last edited by seb421 on Tue Mar 19, 2013 1:49 am, edited 6 times in total.

ヨシムラ

MOT - 10/04/2015

TAX - 30/11/14

INSURANCE - MCE - Expires 12/04/2015 (Midnight)

ACCIDENT CALL - 0871 2227910

RAC - 0800 1977830 - 03_MCECAB90013033

MOT - 10/04/2015

TAX - 30/11/14

INSURANCE - MCE - Expires 12/04/2015 (Midnight)

ACCIDENT CALL - 0871 2227910

RAC - 0800 1977830 - 03_MCECAB90013033

Re: What set up are you running, and how is it for you?

I'm constantly playing with mine.  changing things and experimenting. I have had my carbs off 16 times since 06/06/2012 according to my notes.

changing things and experimenting. I have had my carbs off 16 times since 06/06/2012 according to my notes.

My current settings

AIRBOX

MAIN - Berrnie Morgan Mod

VELOCITY STACKS - Two Standard Long Fitted

FILTER - BMC Street Filter

EXHAUST

PIPES - Standard but modified left outlet with smaller diameter 90degree mandrel

CANS - SP1 Arata Titanim

EXHAUST STYLE - Custom Upswept

FRONT CARB

MAIN AIR JET DRILLED - No

MAIN - #178 KeiHin/FP

Emulsion Tube the Same as Rear

NEEDLES - Factory Pro TI on 2nd clip from the bottom (pointy end) with standard 10though shim

SLIDES - Standard not drilled or blocked

SPRINGS - Standard

PILOT - #45

A/F SCREW - Done by ear & Blip test

REAR CARB

MAIN AIR JET DRILLED - No

MAIN - #180 KeiHin/FP

NEEDLES - Factory Pro TI on 2nd clip from the bottom (pointy end) with standard 10though removed and 20thou shim added, so 10 though more than the front

SLIDES - Standard not drilled or blocked

SPRINGS - Standard

PILOT - #45

A/F SCREW - Done by ear & Blip test

OTHER VARIABLES

TPS - 500 ohms

IGNITION ADVANCER - Standard

COILS - Stick Coil Conversion

GEARING - Standard

CLUTCH - N/A

FLYWHEEL - Standard

PISTONS - Standard

CAMS - Standard

OIL COOLER - Standard

ENGINE OIL - N/A

DYNO SHEET - Seat of Pants

Bike rides spot on at full running temp but fuelling, who knows, it drinks the way I ride, but is probably a bit too rich low down as I can't use the choke when first starting. I previously had the needle 1 clip higher and there was a bit of carb cough/splutter at around 3500-4000rpm. I suspect I need larger mains then lean off the needles but CBA changing until I get a few dyno runs to see which is best for speed and pull from 7500rpm onwards, I will then worry about needles and then the pilot circuit. Tune it in the right order, no point worrying about the needles until the mains are done.

the way I ride, but is probably a bit too rich low down as I can't use the choke when first starting. I previously had the needle 1 clip higher and there was a bit of carb cough/splutter at around 3500-4000rpm. I suspect I need larger mains then lean off the needles but CBA changing until I get a few dyno runs to see which is best for speed and pull from 7500rpm onwards, I will then worry about needles and then the pilot circuit. Tune it in the right order, no point worrying about the needles until the mains are done.

Still not decided whether to keep the BMC filter or stick a standard in. What I might do is set these carbs up for standard filter and block a slide hole in each slide and shim standard needles. My spare carbs I can drill out the Main air jets, stick the bmc filter and FP kit in and jet to suit. I would also put a flow commander in this too, but then I need another airbox. That would be ideal, two sets of carbs with different setup's that I can swap over as I please.

Then I would need a third set of carbs to play and experiment with for fun. Or use for testing other things in the future like airbox mods or something.

(:-})

My current settings

AIRBOX

MAIN - Berrnie Morgan Mod

VELOCITY STACKS - Two Standard Long Fitted

FILTER - BMC Street Filter

EXHAUST

PIPES - Standard but modified left outlet with smaller diameter 90degree mandrel

CANS - SP1 Arata Titanim

EXHAUST STYLE - Custom Upswept

FRONT CARB

MAIN AIR JET DRILLED - No

MAIN - #178 KeiHin/FP

Emulsion Tube the Same as Rear

NEEDLES - Factory Pro TI on 2nd clip from the bottom (pointy end) with standard 10though shim

SLIDES - Standard not drilled or blocked

SPRINGS - Standard

PILOT - #45

A/F SCREW - Done by ear & Blip test

REAR CARB

MAIN AIR JET DRILLED - No

MAIN - #180 KeiHin/FP

NEEDLES - Factory Pro TI on 2nd clip from the bottom (pointy end) with standard 10though removed and 20thou shim added, so 10 though more than the front

SLIDES - Standard not drilled or blocked

SPRINGS - Standard

PILOT - #45

A/F SCREW - Done by ear & Blip test

OTHER VARIABLES

TPS - 500 ohms

IGNITION ADVANCER - Standard

COILS - Stick Coil Conversion

GEARING - Standard

CLUTCH - N/A

FLYWHEEL - Standard

PISTONS - Standard

CAMS - Standard

OIL COOLER - Standard

ENGINE OIL - N/A

DYNO SHEET - Seat of Pants

Bike rides spot on at full running temp but fuelling, who knows, it drinks

Still not decided whether to keep the BMC filter or stick a standard in. What I might do is set these carbs up for standard filter and block a slide hole in each slide and shim standard needles. My spare carbs I can drill out the Main air jets, stick the bmc filter and FP kit in and jet to suit. I would also put a flow commander in this too, but then I need another airbox. That would be ideal, two sets of carbs with different setup's that I can swap over as I please.

Then I would need a third set of carbs to play and experiment with for fun. Or use for testing other things in the future like airbox mods or something.

(:-})

==============================Enter the Darkside

- lloydie

- Posts: 20928

- Joined: Mon Jan 17, 2011 11:16 pm

- Location: In the garage somewhere in Coventry

Re: What set up are you running, and how is it for you?

AIRBOX

MAIN - Gutted

SNORKEL - Standard

LID - Flap removed

VELOCITY STACKS - Two Long bulit stacks

FILTER - k&n Filter

EXHAUST

PIPES - Lloydie 2-1

CANS - Leo vince

STYLE - Upswept

FRONT CARB

MAIN AIR JET DRILLED - No

MAIN - #190 Dyno Jet

EMULSION TUBE - Standard front

NEEDLES - Dyno Jet on 3rd clip from bottom

SLIDES - 3rd hole drilled

SPRINGS - Standard

PILOT - #48

A/F SCREW - 1.50

REAR CARB

MAIN AIR JET DRILLED - No

MAIN - #190 Dyno Jet

EMULSION TUBE - Standard rear

NEEDLES - Dyno Jet on 3rd up

SLIDES - drilled 3rd hole

SPRINGS - Standard

PILOT - #48

A/F SCREW - 1.50 out

OTHER VARIABLES

TPS - 500 ohms

IGNITION ADVANCER +4'

COILS - Stick Coil Conversion

GEARING - 15-41

CLUTCH - EBC Heavy duty Clutch & Springs

FLYWHEEL - Lightened

PISTONS - Standard

CAMS - Standard

OIL COOLER - Sp1 4 row

ENGINE OIL - Halfords 10w/40 semi

OTHER -

still needs a little work in the midrange

MAIN - Gutted

SNORKEL - Standard

LID - Flap removed

VELOCITY STACKS - Two Long bulit stacks

FILTER - k&n Filter

EXHAUST

PIPES - Lloydie 2-1

CANS - Leo vince

STYLE - Upswept

FRONT CARB

MAIN AIR JET DRILLED - No

MAIN - #190 Dyno Jet

EMULSION TUBE - Standard front

NEEDLES - Dyno Jet on 3rd clip from bottom

SLIDES - 3rd hole drilled

SPRINGS - Standard

PILOT - #48

A/F SCREW - 1.50

REAR CARB

MAIN AIR JET DRILLED - No

MAIN - #190 Dyno Jet

EMULSION TUBE - Standard rear

NEEDLES - Dyno Jet on 3rd up

SLIDES - drilled 3rd hole

SPRINGS - Standard

PILOT - #48

A/F SCREW - 1.50 out

OTHER VARIABLES

TPS - 500 ohms

IGNITION ADVANCER +4'

COILS - Stick Coil Conversion

GEARING - 15-41

CLUTCH - EBC Heavy duty Clutch & Springs

FLYWHEEL - Lightened

PISTONS - Standard

CAMS - Standard

OIL COOLER - Sp1 4 row

ENGINE OIL - Halfords 10w/40 semi

OTHER -

still needs a little work in the midrange

Re: What set up are you running, and how is it for you?

My current settings

AIRBOX

MAIN - Standard

SNORKEL - Standard

LID - Standard

VELOCITY STACKS - Standard

FILTER - Standard

EXHAUST

PIPES - Standard

CANS - Leo Vince

STYLE - Standard

FRONT CARB

MAIN AIR JET DRILLED - No

MAIN - #180 Dyno Jet

EMULSION TUBE - Standard front

NEEDLES - Dyno Jet on 4th clip

SLIDES - Standard not drilled or blocked

SPRINGS - Standard

PILOT - Standard

A/F SCREW - 2.00

REAR CARB

MAIN AIR JET DRILLED - No

MAIN - #180 Dyno Jet

EMULSION TUBE - Standard rear

NEEDLES - Dyno Jet on 4th clip

SLIDES - Standard not drilled or blocked

SPRINGS - Standard

PILOT - Standard

A/F SCREW - 2.00

OTHER VARIABLES

TPS - Standard

IGNITION ADVANCER - Standard

COILS - Standard

GEARING - Standard

CLUTCH - Standard

FLYWHEEL - Standard

PISTONS - Standard

CAMS - Standard

OIL COOLER - Standard

ENGINE OIL -

OTHER -

DYNO SHEET -

How does it feel; Feels like the power curve shows, smooth, progressive, no dips or surges in power that I can feel, getting progressively stronger. I dont tend to spend much time in the upper rev range, can't see the point on a twin.

AIRBOX

MAIN - Standard

SNORKEL - Standard

LID - Standard

VELOCITY STACKS - Standard

FILTER - Standard

EXHAUST

PIPES - Standard

CANS - Leo Vince

STYLE - Standard

FRONT CARB

MAIN AIR JET DRILLED - No

MAIN - #180 Dyno Jet

EMULSION TUBE - Standard front

NEEDLES - Dyno Jet on 4th clip

SLIDES - Standard not drilled or blocked

SPRINGS - Standard

PILOT - Standard

A/F SCREW - 2.00

REAR CARB

MAIN AIR JET DRILLED - No

MAIN - #180 Dyno Jet

EMULSION TUBE - Standard rear

NEEDLES - Dyno Jet on 4th clip

SLIDES - Standard not drilled or blocked

SPRINGS - Standard

PILOT - Standard

A/F SCREW - 2.00

OTHER VARIABLES

TPS - Standard

IGNITION ADVANCER - Standard

COILS - Standard

GEARING - Standard

CLUTCH - Standard

FLYWHEEL - Standard

PISTONS - Standard

CAMS - Standard

OIL COOLER - Standard

ENGINE OIL -

OTHER -

DYNO SHEET -

How does it feel; Feels like the power curve shows, smooth, progressive, no dips or surges in power that I can feel, getting progressively stronger. I dont tend to spend much time in the upper rev range, can't see the point on a twin.

" It was 2 minutes 5 minutes ago "

- BigVeeGrin

- Posts: 2521

- Joined: Wed Feb 17, 2010 1:41 pm

- Location: Glasgow

Re: What set up are you running, and how is it for you?

Standard all the way as far as I know. Need to get in there and find out as it could have been modded by previous owners. Always taken the view in the past that a) don't understand all this b) margins for improvement are not likely to be that noticeable for my ability given that road surface, temperature, my concentration, how tired I am and so on make more of a difference. How wrong I could be especially post dyno-day

Re: What set up are you running, and how is it for you?

My current settings

AIRBOX

MAIN - Standard

SNORKEL - Standard

LID - Standard

VELOCITY STACKS - Standard

FILTER - Standard

EXHAUST

PIPES - Standard

CANS - Pipe Werx

STYLE - Low- standard

FRONT CARB

MAIN AIR JET DRILLED - No

MAIN - #172 FP

EMULSION TUBE - Standard front

NEEDLES - FP top clip (blunt end-lean)

SLIDES - Standard not drilled or blocked

SPRINGS - Standard

PILOT - #48

A/F SCREW - 2

REAR CARB

MAIN AIR JET DRILLED - No

MAIN - #175 stock

EMULSION TUBE - Standard rear

NEEDLES - FP top clip (blunt end-lean)

SLIDES - Standard not drilled or blocked

SPRINGS - Standard

PILOT - #48

A/F SCREW - 2

OTHER VARIABLES

TPS - 500 ohms

IGNITION ADVANCER - FP +4

COILS - Stick Coil Conversion

GEARING - -1 front, +1 rear

CLUTCH - Standard

FLYWHEEL - Standard

PISTONS - Standard

CAMS - Standard

OIL COOLER - Standard

ENGINE OIL - Semi Synthetic

OTHER - Rider- non standard!

DYNO SHEET -

Set up by Dyno guy in Grimsby. Used FP 1.7 kit but no drilling. Once above 3500rpm bike is real smooth. It has a hesitation when pulling away & at any other regime when rpm is about 3000. Generally happy but needs lower end sorting out and I have a medium term desire to drill MAJ and make use of BMC street filter.

Regards, Griff.

AIRBOX

MAIN - Standard

SNORKEL - Standard

LID - Standard

VELOCITY STACKS - Standard

FILTER - Standard

EXHAUST

PIPES - Standard

CANS - Pipe Werx

STYLE - Low- standard

FRONT CARB

MAIN AIR JET DRILLED - No

MAIN - #172 FP

EMULSION TUBE - Standard front

NEEDLES - FP top clip (blunt end-lean)

SLIDES - Standard not drilled or blocked

SPRINGS - Standard

PILOT - #48

A/F SCREW - 2

REAR CARB

MAIN AIR JET DRILLED - No

MAIN - #175 stock

EMULSION TUBE - Standard rear

NEEDLES - FP top clip (blunt end-lean)

SLIDES - Standard not drilled or blocked

SPRINGS - Standard

PILOT - #48

A/F SCREW - 2

OTHER VARIABLES

TPS - 500 ohms

IGNITION ADVANCER - FP +4

COILS - Stick Coil Conversion

GEARING - -1 front, +1 rear

CLUTCH - Standard

FLYWHEEL - Standard

PISTONS - Standard

CAMS - Standard

OIL COOLER - Standard

ENGINE OIL - Semi Synthetic

OTHER - Rider- non standard!

DYNO SHEET -

Set up by Dyno guy in Grimsby. Used FP 1.7 kit but no drilling. Once above 3500rpm bike is real smooth. It has a hesitation when pulling away & at any other regime when rpm is about 3000. Generally happy but needs lower end sorting out and I have a medium term desire to drill MAJ and make use of BMC street filter.

Regards, Griff.

Last edited by Griff1977 on Fri Mar 22, 2013 7:54 pm, edited 2 times in total.

KriegerCCTs,HEL oil lines,+4 advancer,+1/-1 sprockets,6mm spacer,CBR1k Sidestand,'07 R1 R/R,HyperPro springs F&R,Pipe Werx SL Carbons,Oxford sports hot grips,Mori style belly

Immediate plans:Clean it!

Immediate plans:Clean it!

- agentpineapple

- Posts: 15124

- Joined: Sat Mar 26, 2011 9:16 pm

Re: What set up are you running, and how is it for you?

carl, why don't you take the bmc and standard filter with you and have two power runs, one of each, also would the style of spark plug make any difference, iirc your using those new brisk plugs?

HEY YOU GUYS!!!!!!

Re: What set up are you running, and how is it for you?

My current settings (today, anyway, they'll be different tomorrow, as I can't leave well enough alone!)

AIRBOX

MAIN - Gutted, enlarged by removing corner sections, also a 10mm spacer section installed above box but below filter made form a section of an old lid, plus an outer cutout from an old filter. Longer airbox screws to hold it together, spacers (20mm) under front tank mount.

SNORKEL - ENlarged, foam removed and a bridge made so that it has a larger cross-sectional area throughout. Centre web removed.

LID - Flap removed, posts removed.

VELOCITY STACKS - currently one short one long std, but still playing with hybrid SP1 rolled tops grafted onto std bases.

FILTER - K+N.

BREATHERS - routed to and external catch tank and breather. Bit of a bodge, but you can't see it (except for the little cone pleated filter, poking out from under the tank LH side). Not yet happy with this, as you get a small amount of condensation collecting in the tubes between the engine cam covers and the catch tank- not ideal. Because I used clear tubing you can see this, and it doesn't take long to pull off and clean out. I'd advise checking yours if you've done this haven't used clear tubing.

EXHAUST

PIPES - Std

CANS - MIG High level, not much in the way of baffling material.

STYLE - High level

FRONT CARB

MAIN AIR JET DRILLED - Not yet, although drills arrived yesterday- front 1.1mm dia, rear 1.4mm dia.

MAIN - #190 Keihin

EMULSION TUBE - #48

NEEDLES - Factory Pro on 2nd clip from top

SLIDES - Standard not drilled or blocked

SPRINGS - Std, probably tired by now

PILOT - #50 (but working from memory, so not sure, and don't feel like taking it apart to look atm)

A/F SCREW - 2.00 out

REAR CARB

MAIN AIR JET DRILLED - Not yet

MAIN - #195 Keihin

EMULSION TUBE - #48

NEEDLES - Factory Pro, 2nd from top

SLIDES - Standard not drilled or blocked

SPRINGS - Standard, knackered

PILOT - #50 (AFAIR)

A/F SCREW - 2.00 out

OTHER VARIABLES

TPS - 500 ohms

IGNITION ADVANCER -4 degrees advanced, Factory Pro

COILS - Stick Coil Conversion

GEARING - 15T front (STd is 16)

CLUTCH - EBC Kevlar Series Street Racing Clutch & Springs

FLYWHEEL - Standard

PISTONS - JE 11.6:1 high compression pistons, Honda rings. Std bore, no oversize.

CAMS - Standard cams reground by Newman Cams, Kent, to give just over 1mm extra lift, @10 degrees more dwell. Currently on std lobe centre settings and overlap.

HEADS - gasflowed by me, more cleaned up and polished than reshaped, on this occasion, but I have some plans for substantial head work for the front cyl, and oversize inlet valves are also on the cards

OIL COOLER - 4 - row SP1 conversion

ENGINE OIL - Castrol Power 1 10w/30 Semi Synthetic

OTHER - Currently has the quietening gear in, but this will come out again next time the clutch cover's off.

Currently running stock clutch m/c, but I have a semi-hydraulic setup (hydraulic top end, tiny MC, then a small cylinder near the lower end converts to a cable-type rod and nipple, which is mated to a Varadero case) ready to install and test as soon as the drags trip warms up, to see if it cures clutch grab.

Braced rear SA, Blade brace welded and powder coated.

WP springs front, 140mm air gap, 7.5. weight oil.

Hagon remote adjustable shock rear, better than std but not perfect, cheap though.

Braking Wave discs all round, SP1 MC, braided hoses.

Carbon undertray

100/85 headlight bulb, separate relays for each

12v waterproof cig lighter socket

Optimate 4 charger socket conversion

Gear indicator c/w voltage display

Ultrabright LED sidelight

Clear rear light, built-in indicators, secondary indicators also fitted.

Mirror indicators, secondary indicators also fitted

Titax long series levers fitted.

DB screen, MRA I think

Homemade QA throttle, not as quick action as I'd like so that's up for a rebuild as soon as there's a sunny day.

14AH Motobatt 4 terminal battery fitted TAM, but there will be a lightweight one in for the summer.

I'm sure there's more....

DYNO SHEET -

115bhp or thereabouts at present with boosted torque, quick enough for the road but I need more on the drag strip. Watch this space.

Jetting and carbs set up by Tony at HM Racing, Edenbridge, he knows his stuff, sho' nuff.

Not perfect fuelling around 3500, but good enough, and clean top end/mid range.

Fixing the low end gives problems elsewhere, so I'll live with it for now.

PLANS - Major reporting on a front head, to see if I'm right that the fact that only one of the exhaust valves lines up with the exhaust entry is horribly inefficient. But this means cutting into the water jacket, also removing one of the exhaust mounting studs, and so I'm thinking about an oval port and exhaust header section. Not easy.

Funnily enough the rear head's fine, so that just needs opening up a little.

Forks are tired, I need new taper roller head bearings, internal fork bushes, and the front brakes need their spring TLC.

I fancy building my own bigger-bore exhaust system, Yeti has kindly loaned me his Yosh system to get some ideas from, it's Ti but I'll probably stick with stainless for now until I'm happy with it, then see if I can afford a Ti copy of the finished article.

I still have one idea to play with, which is to separate the two intakes in the airbox (two separate airboxes?). There's no breathing advantage, but you could then run a Big Bang configuration engine, with the cam timing 180 degrees out,m and it would still rev out, which it won't do with a single airbox.

No idea what it will do on the dyno, or how it will ride, but is seems like fun to play with.....

As soon as all that's finished I'll clean it.

Once that lot's done I'll sell it and start again on an SP2.

AIRBOX

MAIN - Gutted, enlarged by removing corner sections, also a 10mm spacer section installed above box but below filter made form a section of an old lid, plus an outer cutout from an old filter. Longer airbox screws to hold it together, spacers (20mm) under front tank mount.

SNORKEL - ENlarged, foam removed and a bridge made so that it has a larger cross-sectional area throughout. Centre web removed.

LID - Flap removed, posts removed.

VELOCITY STACKS - currently one short one long std, but still playing with hybrid SP1 rolled tops grafted onto std bases.

FILTER - K+N.

BREATHERS - routed to and external catch tank and breather. Bit of a bodge, but you can't see it (except for the little cone pleated filter, poking out from under the tank LH side). Not yet happy with this, as you get a small amount of condensation collecting in the tubes between the engine cam covers and the catch tank- not ideal. Because I used clear tubing you can see this, and it doesn't take long to pull off and clean out. I'd advise checking yours if you've done this haven't used clear tubing.

EXHAUST

PIPES - Std

CANS - MIG High level, not much in the way of baffling material.

STYLE - High level

FRONT CARB

MAIN AIR JET DRILLED - Not yet, although drills arrived yesterday- front 1.1mm dia, rear 1.4mm dia.

MAIN - #190 Keihin

EMULSION TUBE - #48

NEEDLES - Factory Pro on 2nd clip from top

SLIDES - Standard not drilled or blocked

SPRINGS - Std, probably tired by now

PILOT - #50 (but working from memory, so not sure, and don't feel like taking it apart to look atm)

A/F SCREW - 2.00 out

REAR CARB

MAIN AIR JET DRILLED - Not yet

MAIN - #195 Keihin

EMULSION TUBE - #48

NEEDLES - Factory Pro, 2nd from top

SLIDES - Standard not drilled or blocked

SPRINGS - Standard, knackered

PILOT - #50 (AFAIR)

A/F SCREW - 2.00 out

OTHER VARIABLES

TPS - 500 ohms

IGNITION ADVANCER -4 degrees advanced, Factory Pro

COILS - Stick Coil Conversion

GEARING - 15T front (STd is 16)

CLUTCH - EBC Kevlar Series Street Racing Clutch & Springs

FLYWHEEL - Standard

PISTONS - JE 11.6:1 high compression pistons, Honda rings. Std bore, no oversize.

CAMS - Standard cams reground by Newman Cams, Kent, to give just over 1mm extra lift, @10 degrees more dwell. Currently on std lobe centre settings and overlap.

HEADS - gasflowed by me, more cleaned up and polished than reshaped, on this occasion, but I have some plans for substantial head work for the front cyl, and oversize inlet valves are also on the cards

OIL COOLER - 4 - row SP1 conversion

ENGINE OIL - Castrol Power 1 10w/30 Semi Synthetic

OTHER - Currently has the quietening gear in, but this will come out again next time the clutch cover's off.

Currently running stock clutch m/c, but I have a semi-hydraulic setup (hydraulic top end, tiny MC, then a small cylinder near the lower end converts to a cable-type rod and nipple, which is mated to a Varadero case) ready to install and test as soon as the drags trip warms up, to see if it cures clutch grab.

Braced rear SA, Blade brace welded and powder coated.

WP springs front, 140mm air gap, 7.5. weight oil.

Hagon remote adjustable shock rear, better than std but not perfect, cheap though.

Braking Wave discs all round, SP1 MC, braided hoses.

Carbon undertray

100/85 headlight bulb, separate relays for each

12v waterproof cig lighter socket

Optimate 4 charger socket conversion

Gear indicator c/w voltage display

Ultrabright LED sidelight

Clear rear light, built-in indicators, secondary indicators also fitted.

Mirror indicators, secondary indicators also fitted

Titax long series levers fitted.

DB screen, MRA I think

Homemade QA throttle, not as quick action as I'd like so that's up for a rebuild as soon as there's a sunny day.

14AH Motobatt 4 terminal battery fitted TAM, but there will be a lightweight one in for the summer.

I'm sure there's more....

DYNO SHEET -

115bhp or thereabouts at present with boosted torque, quick enough for the road but I need more on the drag strip. Watch this space.

Jetting and carbs set up by Tony at HM Racing, Edenbridge, he knows his stuff, sho' nuff.

Not perfect fuelling around 3500, but good enough, and clean top end/mid range.

Fixing the low end gives problems elsewhere, so I'll live with it for now.

PLANS - Major reporting on a front head, to see if I'm right that the fact that only one of the exhaust valves lines up with the exhaust entry is horribly inefficient. But this means cutting into the water jacket, also removing one of the exhaust mounting studs, and so I'm thinking about an oval port and exhaust header section. Not easy.

Funnily enough the rear head's fine, so that just needs opening up a little.

Forks are tired, I need new taper roller head bearings, internal fork bushes, and the front brakes need their spring TLC.

I fancy building my own bigger-bore exhaust system, Yeti has kindly loaned me his Yosh system to get some ideas from, it's Ti but I'll probably stick with stainless for now until I'm happy with it, then see if I can afford a Ti copy of the finished article.

I still have one idea to play with, which is to separate the two intakes in the airbox (two separate airboxes?). There's no breathing advantage, but you could then run a Big Bang configuration engine, with the cam timing 180 degrees out,m and it would still rev out, which it won't do with a single airbox.

No idea what it will do on the dyno, or how it will ride, but is seems like fun to play with.....

As soon as all that's finished I'll clean it.

Once that lot's done I'll sell it and start again on an SP2.

It's not falling off, it's an upgrade opportunity.