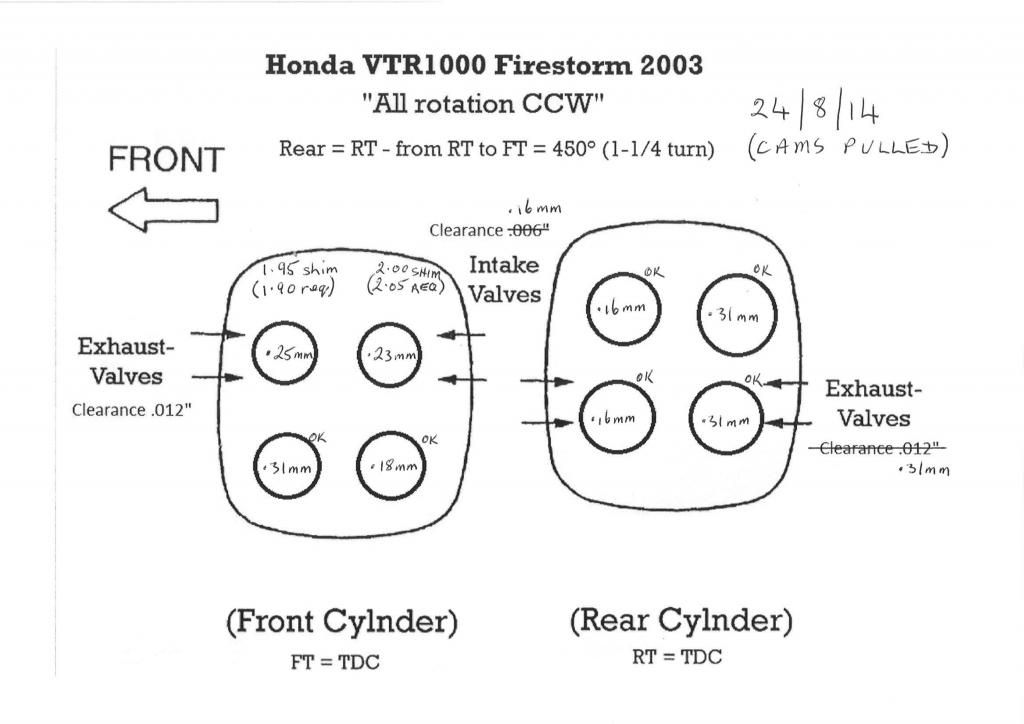

Pain in the butt doing valve clearances!!! especially if you don't have a shim kit to hand (9.48mm shims on these bikes) as it means removing the cams, measuring the shim, doing your sums and ordering the right size replacement shim either from Honda who I think have a finer range of measurements or 3rd party like hotcam which are in steps of .5mm and some other kits in steps of .25mm increments.

Calculations are as follows: Measure the clearance (lash), and minus the specified clearance. Then measure the shim thickness (do not trust and markings on them as they can wear) you will need a micrometer, preferably in .25 increments for measurements. Then add the shim thickness to your clearance minus specified clearance calculation. Inlet 0.16mm and Exhaust 0.31mm + or - 0.03mm.

You will need a magnet on a stick, flexible magnet or something to lift the buckets off along with the shim stuck to the magnet on the inside of the bucket. Be very careful not to drop any shims inside the engine. Use rags to block passages if needed.

Note for accurate clearance measurements, it should be done with everything tightened down including the CCT as the pressure that the CCT puts on the cam chain can make a slight difference to clearance on the chain side of the cams. Also the torque on the 4 cam cap bolts for each cam makes a big difference. In fact if you was to tighten the cam cap bolt, say 1/2 a turn, above the rear inlet that measured in at 0.07 thou, it could easily end up being 0.06 thou clearance. Be very careful with these bolts as they can snap in the cylinder head if overtightened. Remember what I was saying about torque wrenches and stretched bolts. In fact unless your using new bolts I would recommend not doing these up to the specified torque in the manual and keep them just under to be on the safe side.

Try to keep things consistent. Go slow, take your time and check things and then double check things. Don't mix up any cams, cam caps, buckets, shims etc and keep everything as is because parts wear in together. Even after replacing shims and checking the clearances again you may find one or two slightly off because of cam cap tension. This is where the shim kits come in handy as it's easy to swap one out for the next size up or down.

When putting the cam chain back over the sprockets, pull it taught on the opposite side to the tensioner and sit that cam in place with the timing mark lined up before moving onto the other cam and sliding the chain over.

Give all parts a good coating of oil on re-assembly, I also pour a little over the camshafts and turn the engine over by hand a few times before firing it up.

It might be worth changing the thread title to something more relevant now. Maybe Airbox, CCT Stopper and Valve clearances

(:-})