Big_Jim59 wrote:I worked on a rode many a three cylinder Triumph. They were really sweet. They made really good smooth power and not like a Japanese four. The power was there just off idle. The sound was fantastic from a rumbling purr at idle to a throaty shreak at full cry. The weight was rather high but because the C of G was really low the handling was really great. They were designed really as an extra cylinder on the Triumph 500, which still if my favorite Triumph twin. That engine is bullet proof. There were two things wrong with the Triumph threes, they were built horribly. The Japanese knew that you couldn't get away with building junk but the Brits and the American's hadn't figured that out. There was something wrong with every three cylinder we sold and sometimes there were things that were majorly wrong. The second factor in their demise was the advent of the Honda CB750. It was just so much more bike. It made the Triumphs look dated and they were. Richard Mann won the Dayton 200 (a grueling race with no slow sections) in 1970 on a Honda 750. In 1971 he won on a BSA Rocket Three. The difference is the Honda win destroyed the motorcycle. He nursed it to the finish line with it drinking oil. Not so the BSA. The BSA/Triumph three was a truly great engine that was too little too late.

I am quite familiar with the Triton. Cut new or redrill the engine plates and you were good to go. I never had much dealings with the old pre-unit Triumphs. I wonder if the addition of higher compression pistons didn't serve up a while plate of bottom end trouble. The later unit twins would break cranks. Sammy, a particularly good race tuner said of the 650 units Triumph "it will make 42 real horsepower and at 42.5 it will break the crank." I have seen a few broken cranks but in those days it was hard to tell if it was from performance or just bad OEM parts.

I am glad to be at, what I consider, the bottom of the project. The mystery has been reveled and now, all that is left is spending money and careful reassembly.

I think you hit the nail on the head there Jim with the British market being lost to the Japanese. The Japanese took our British designs and spent money on R&D to produce a better quality motorcycle. I feel the British motorcycle industry was convinced they had the best mass produced motorcycles in the world, but failed to plough back some of the profits into R&D to move with the times to make better motorcycles. When you look at many things that have come from the Japanese in motorcycle design, the British motorcycles had already done it, just not as well.

I had not heard of a Triumph 650 pre-unit crank breaking (although that doesn't necessarily mean there weren't any), and I know they used them in grass track racing engines in the outfits (sidecars), so they got a hard life there. I believe they preferred the 3 piece crankshaft for racing engines, IIRC the reasoning behind that was the 3 piece crankshaft had more give in it than a solid one piece crankshaft had.

I thought you'd be familiar with the Triton Jim

Big_Jim59 wrote:darkember wrote:Did you ever find the missing bearing? That is the weirdest part to the whole story.

No, the bearing shell was just gone. I can only guess that the PO opened the sump, removed the rod bearing, declared it toast, put the rod cap back on and the pan together and sold it as a "project bike" that just needed reassembly.

That really is what I've been thinking all along.

Big_Jim59 wrote:Due to the damage I found around the main bearing and the indentation made when the bearing locked to the crank and spun, I have ordered a used set of cases off eBay. The seller is including the matching pistons. These are from the same seller that supplied me with the crank and rods so I am pretty sure they are all from the same engine. After a bit of reflection, I spent an additional $25 and got the oil pump from that seller as well. I'll just replace my engine one piece at a time. The seller claims that this engine only had 9K miles on it so I should have a good solid bottom end when I am done.

I am pretty sure the engine would live if I used the old components but I would be forever worried about it (I am a cranked up worrier after all) and I would never feel comfortable running it hard or selling it along to someone else. It will set my time line back a bit as I will have to reevaluate my bearing order after I examine the case for the code letters.

Might as well do it right!

I'm sure you've done the right thing there, if you're anything like me you would be kicking yourself later on when the bike is back on the road for not changing the crankcases while you had it all apart.

Big_Jim59 wrote:

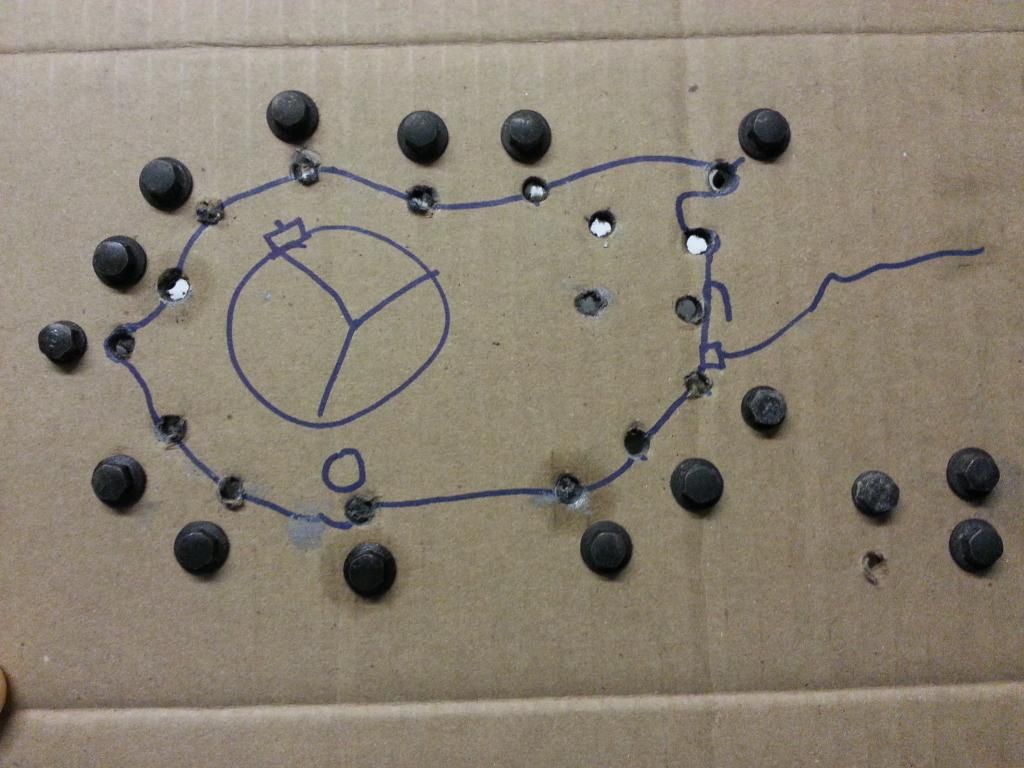

I know it is silly but I make rough drawings of the bolt layout on a piece of pizza box and then make holes in it to match the bolt pattern. I then jam the bolts into the cardboard holding them in the original order they came out. No guessing.

Me too

but it's usually cereal boxes not pizza boxes

Varastorm wrote:Hi Jim, stumbled over this whilst reading about cylinder head porting on the US Superhawk site.

Its an old thread about things to watch out for during a rebuild

Good find Vara

Good advice

tony.mon wrote:

Back to the Rocket Three and Trident, I had one of the first hundred Tridents built- four speed box, drum brakes front and rear, ray-gun pipes. Lovely to look at, but heavy, and the brakes were horrible- you had to pull them on as you passed the pub before the one you wanted to stop at.

Should have kept it, it was about the only bike I've ever had that would have increased in value but hey.

I bet you wished you'd kept it Tony, I know I wish I still had many of my old British bikes, hindsight being a wonderful thing

Jim, Good luck with the rebuild, as you say take your time. Just one question, how on earth do you manage to keep hold of the crankcases when you clean them at the car wash

Please don't tell me you get your wife to hold on to them

Chris.

unless your using new bolts. Engine internals I would be a bit more critical about.