That looks rather special

Chris.

oooh,i like that.neil wrote: ↑Sun Feb 27, 2022 8:34 am https://www.bikeexif.com/ghezzi-brian-moto-guzzi-1100 This article has more information on the Guzzi in the photo I put on earlier post.

first time I have seen that! it is VERY nice!alanfjones1411 wrote: ↑Sun Feb 27, 2022 10:36 amoooh,i like that.neil wrote: ↑Sun Feb 27, 2022 8:34 am https://www.bikeexif.com/ghezzi-brian-moto-guzzi-1100 This article has more information on the Guzzi in the photo I put on earlier post.

Cheers Neil for the linkneil wrote: ↑Sun Feb 27, 2022 8:34 am https://www.bikeexif.com/ghezzi-brian-moto-guzzi-1100 This article has more information on the Guzzi in the photo I put on earlier post.

neil wrote: ↑Sun Feb 27, 2022 8:34 am https://www.bikeexif.com/ghezzi-brian-moto-guzzi-1100 This article has more information on the Guzzi in the photo I put on earlier post.

I don't think they understand me

buzzer wrote: ↑Fri Mar 04, 2022 10:27 amI don't think they understand me

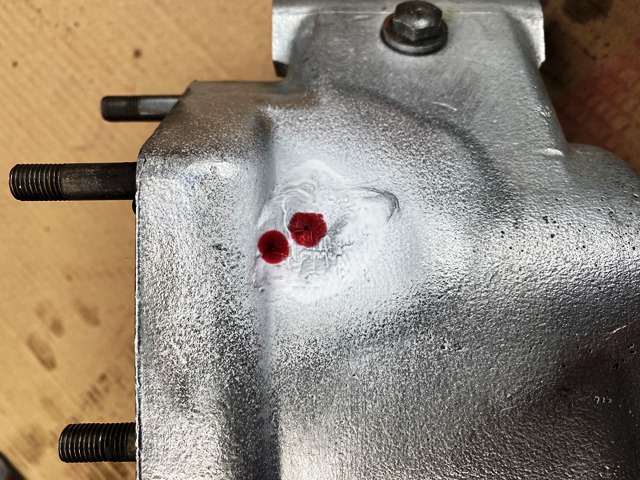

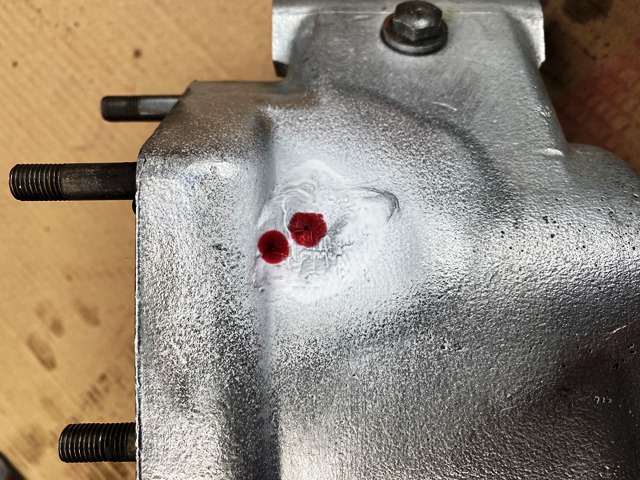

The tank I am using is off a V7… It was cheap to buy because it had a couple of big dents, which I have managed to get out. To do this I had to cut a couple of holes in the bottom to give access with a 20mm bar with a dome on the end, which I then used to knock most of the dent out, just needing a skim of filler. I then welded some plates on the holes and leak tested them with dye penetrant.

I use this a lot, its great for checking for holes and cracks, they show up immediately. fortunately all was good in this case. I prefer doing it this way to filling it with petrol as if you do have a leak its a pain to clean it out again. I have taken to using the dye penetrant on frames before I have them blasted… its surprising how many have cracks! especially Ducati!

A while ago my mate welded an RGV 250 engine mounting on the alloy frame. When he had welded it, he used some dye penetrant around the joints on the frame to check for cracks… There were quite a few! he welded them up and re-checked. Here is a gearbox I recently welded that still had a leak after someone had already welded it, you could not see it with the naked eye, but its easily visible with the dye…

Many thanks for explaining how the three step process worksbuzzer wrote: ↑Sat Mar 05, 2022 11:26 am yes, its a three step process... first a cleaner, let it dry... then a dye, which creeps into the cracks, which you then wipe off after 15 mins, and then the developer, which pulls the dye out of any cracks. when there is a crack, its really obvious.

its brilliant! my mates company make BIG stainless steel tanks (and i mean BIG!!!!) and he uses this on the welds... he sprays from the inside, and uses the developer on the outside in 5 years he has been making the tanks I can only recall twice he has found a leak... but if they had gone to site with a leak, the cost to rectify (after it was filled with sewage) would be massive.

I was there last year when he had a steel section "H" beam in from an architectural company for modification. it was an old beam and before he started work he dye pened the beam in a few stress areas... it had multiple cracksThe architect was there to inspect it and was so impressed at his visit and the fact he had took the initiative to check, he placed a big order for the next job he was doing!