Valve Clearance ?

Valve Clearance ?

Hi All,

first of all, I bought my Storm last September (brought it over from Liverpool) as a city bike... as the XX is getting too heavy during the peak hours. Now I have an issue, where I don't know whether I'm just totally stupid or the timing is completely off on my Storm.

Here is my scenario:

After replacing the CCT with manual Krieger (due to ticking noises) I ran the bike, which - when heated up - still makes the ticking noise. Timing was off on the front cylinder by 1 tooth when I changed the CCT, which has been properly adjusted (I thought). So I decided to strip it all again (yes, I should have done that when doing the CCT)...

Now the service manual states, to put the crankshaft marking on FT, making sure that the cams are pointing up and outwards (with the FI and FE marks straight). Done that, measured the valve clearance; found out I have to do the shims.

But what strikes me most:

The service manual states turn the crankshaft 270 degree to reach the RT mark and then measure the rear cylinder. My issue here is:

1. This doesn't happen for me, it's more like 300 degree to turn. Is this correct?

2. The rear cylinder's cams do not align with the RI and RE marks - they are pointing downwards. Should that be the proper position to measure the valve clearance? I didn't think so...

I hope someone can help... thank you very much in advance!

Cheers,

Marc

first of all, I bought my Storm last September (brought it over from Liverpool) as a city bike... as the XX is getting too heavy during the peak hours. Now I have an issue, where I don't know whether I'm just totally stupid or the timing is completely off on my Storm.

Here is my scenario:

After replacing the CCT with manual Krieger (due to ticking noises) I ran the bike, which - when heated up - still makes the ticking noise. Timing was off on the front cylinder by 1 tooth when I changed the CCT, which has been properly adjusted (I thought). So I decided to strip it all again (yes, I should have done that when doing the CCT)...

Now the service manual states, to put the crankshaft marking on FT, making sure that the cams are pointing up and outwards (with the FI and FE marks straight). Done that, measured the valve clearance; found out I have to do the shims.

But what strikes me most:

The service manual states turn the crankshaft 270 degree to reach the RT mark and then measure the rear cylinder. My issue here is:

1. This doesn't happen for me, it's more like 300 degree to turn. Is this correct?

2. The rear cylinder's cams do not align with the RI and RE marks - they are pointing downwards. Should that be the proper position to measure the valve clearance? I didn't think so...

I hope someone can help... thank you very much in advance!

Cheers,

Marc

Re: Valve Clearance ?

Service manual...is it Haynes one ?

It's wrong FT to RT is 460* or 1 & a 1/4 turns of the fly wheel. When set correctly the the rear cams should point up & in...The fronts at TDC point up & out...

Read this it's all in there. viewtopic.php?f=31&t=28583#p264315

It will run but starts to choke up at anything over 7k revs... bogs down & struggles to pull 60-70...It's 180 * out & both cylinders are fireing at once. It gets to the point where not enough air is getting in to each cylinder so bogs down.

It's wrong FT to RT is 460* or 1 & a 1/4 turns of the fly wheel. When set correctly the the rear cams should point up & in...The fronts at TDC point up & out...

Read this it's all in there. viewtopic.php?f=31&t=28583#p264315

It will run but starts to choke up at anything over 7k revs... bogs down & struggles to pull 60-70...It's 180 * out & both cylinders are fireing at once. It gets to the point where not enough air is getting in to each cylinder so bogs down.

Making up since 2007, sometimes it's true...Honest...

Re: Valve Clearance ?

Mac has got his front mixed up with the back, according to Lloydie this happens sometimes, but I wouldn't know myself

If you're starting at the rear cylinder it's 450 degrees anti-clockwise to to align the front (FT) cylinder timing mark.

In your case you should be getting the RT mark to line up with a 270 degrees anti-clockwise rotation of the crank as you're saying.

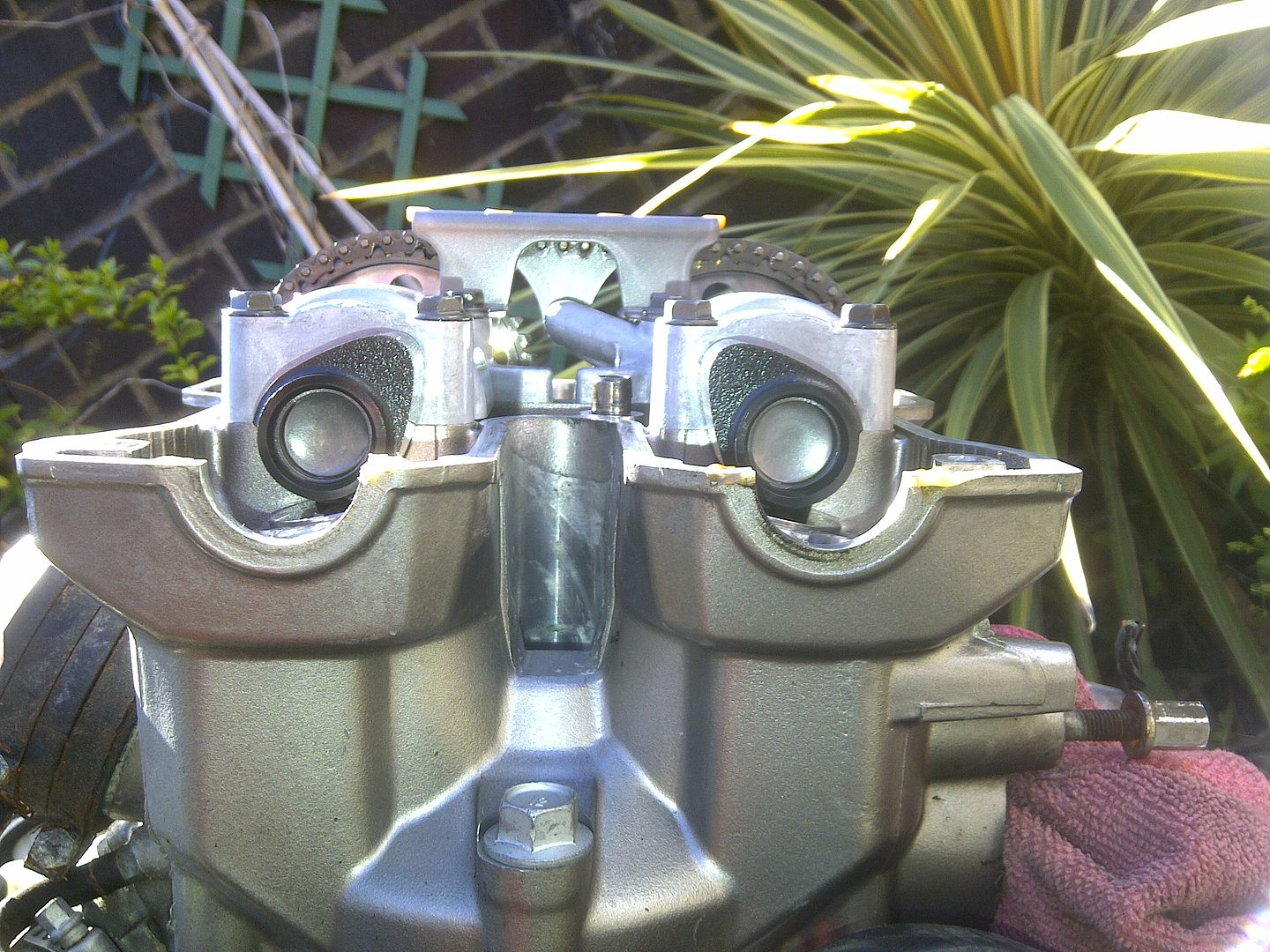

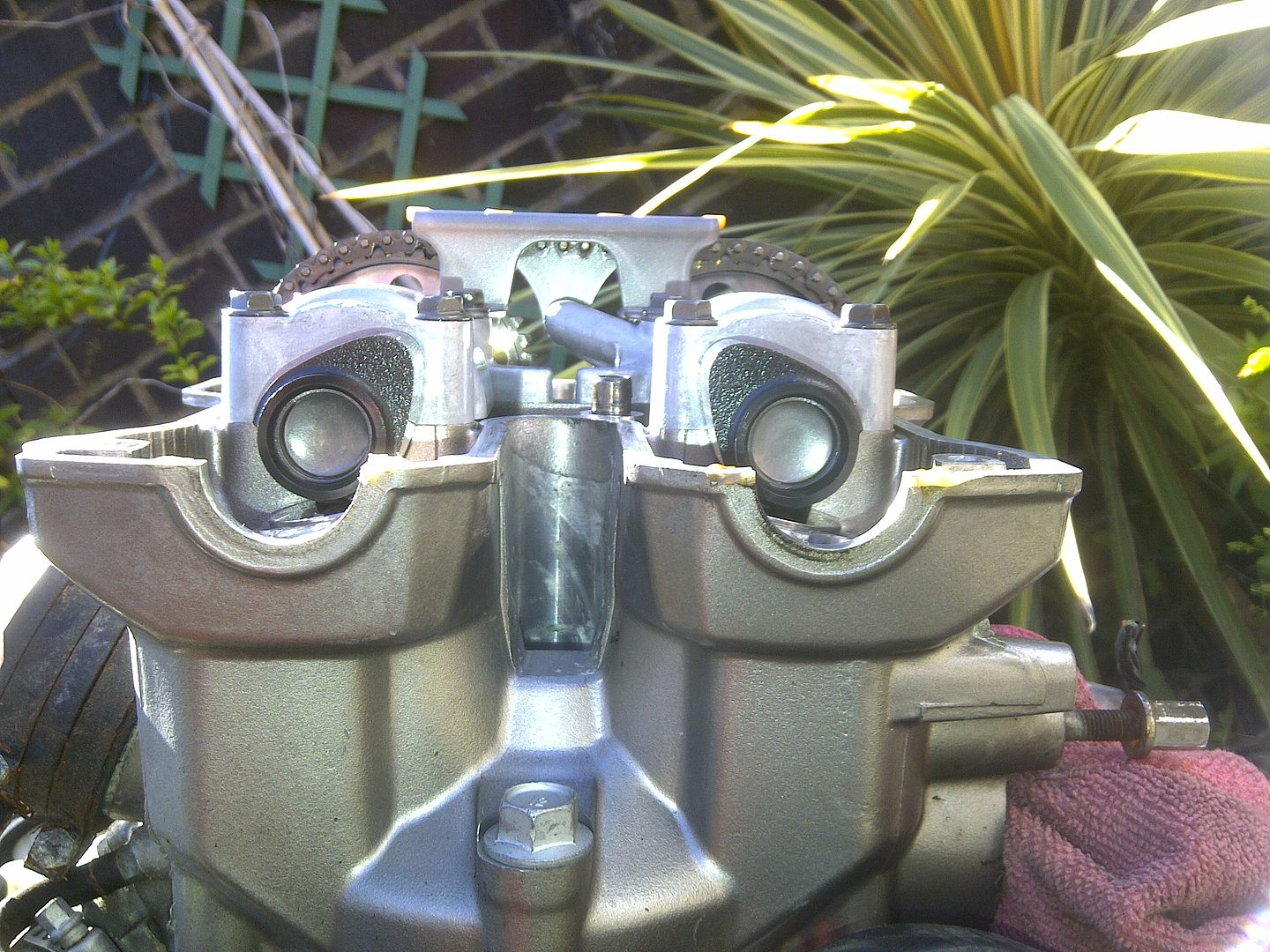

Pinching a photo from Carl's link that Mac posted up for you, the cam's should be in this position for the rear cylinder, facing upwards and slightly inwards

The RI and RE marks should be more or less level with the top of the cylinderhead and facing away from each other.

Just a thought, you are turning the crank anti-clockwise and the FI and FE marks are facing away from each other

and the FI and FE marks are facing away from each other

It sounds like you have the cam lobes facing in the right direction for the front cylinder.

Chris.

If you're starting at the rear cylinder it's 450 degrees anti-clockwise to to align the front (FT) cylinder timing mark.

In your case you should be getting the RT mark to line up with a 270 degrees anti-clockwise rotation of the crank as you're saying.

Pinching a photo from Carl's link that Mac posted up for you, the cam's should be in this position for the rear cylinder, facing upwards and slightly inwards

The RI and RE marks should be more or less level with the top of the cylinderhead and facing away from each other.

Just a thought, you are turning the crank anti-clockwise

It sounds like you have the cam lobes facing in the right direction for the front cylinder.

Chris.

Re: Valve Clearance ?

Hi guys,

thanks for your prompt responses!

So, I had the cam lobes of the front cylinder facing upwards, the FI and FE marks on the cams are level with the cylinder head and facing away from each other (I double checked that 3 times).

Then I turned anti-clockwise 270 degrees (it's more like 290 or 300 but that might be my ratchet), and the rear cylinder lobes are facing downwards... I will have to turn it another 360 to get them facing upwards.

The bike ran good beforehand (apart from the rattling noise from the front cylinder), I changed the CCT and checked the timing and chain. I had to reset the front cylinder 1 teeth (I didn't turn the crankshaft when I did that)

So what that tells me is that the cams are 360 degree out, isn't it?

Cheers,

Marc

thanks for your prompt responses!

So, I had the cam lobes of the front cylinder facing upwards, the FI and FE marks on the cams are level with the cylinder head and facing away from each other (I double checked that 3 times).

Then I turned anti-clockwise 270 degrees (it's more like 290 or 300 but that might be my ratchet), and the rear cylinder lobes are facing downwards... I will have to turn it another 360 to get them facing upwards.

The bike ran good beforehand (apart from the rattling noise from the front cylinder), I changed the CCT and checked the timing and chain. I had to reset the front cylinder 1 teeth (I didn't turn the crankshaft when I did that)

So what that tells me is that the cams are 360 degree out, isn't it?

Cheers,

Marc

Re: Valve Clearance ?

INFO

STARTING FROM TDC compression stroke on the REAR CYLINDER and MOVING TO TDC compression stroke on the FRONT it's 1.1/4 turn (450°) anti-clockwise at the crank. Front Cams lobes UP and OUT.

STARTING FROM TDC compression stroke on the FRONT CYLINDER and MOVING TO TDC compression stroke on the REAR it's only 3/4 turn (270°) anti-clockwise at the crank. Rear Cams lobes UP and IN.

Note it's possible to be 180 out even if everything still lines up. There are no visual clues.

STARTING FROM TDC compression stroke on the REAR CYLINDER and MOVING TO TDC compression stroke on the FRONT it's 1.1/4 turn (450°) anti-clockwise at the crank. Front Cams lobes UP and OUT.

STARTING FROM TDC compression stroke on the FRONT CYLINDER and MOVING TO TDC compression stroke on the REAR it's only 3/4 turn (270°) anti-clockwise at the crank. Rear Cams lobes UP and IN.

Note it's possible to be 180 out even if everything still lines up. There are no visual clues.

==============================Enter the Darkside

Re: Valve Clearance ?

Think of each cylinder separately.

Because the spark happens every time the piston comes to tdc (It's called wasted spark) it's possible to have that cylinder running fine, as is the other one.

It's the amount of crankshaft rotation between each cylinder that's out, the relationship between them not whether each one works ok.

Because the spark happens every time the piston comes to tdc (It's called wasted spark) it's possible to have that cylinder running fine, as is the other one.

It's the amount of crankshaft rotation between each cylinder that's out, the relationship between them not whether each one works ok.

It's not falling off, it's an upgrade opportunity.

Re: Valve Clearance ?

But that means, if I set my front cylinder properly to FT, then rotate 270 and I ‘reset’ the rear cylinder, I can’t go wrong, can I?

Re: Valve Clearance ?

Correct.

You'll need to undo the cam cap castings carefully to allow the cams to come out while they're pushing the valve springs open and then turn them to line up while facing upwards.

You'll need to undo the cam cap castings carefully to allow the cams to come out while they're pushing the valve springs open and then turn them to line up while facing upwards.

It's not falling off, it's an upgrade opportunity.

Re: Valve Clearance ?

I realllly suggest NOT doing this, even if someone has gotten away with it in the past without damage.

The cam lobes should be off the ramp or in the base circle with valves closed before removing the cam journal cap.

Otherwise the risk of distorting the aluminum cap is great as is pulling the last few threads from the head on one or more cam cap fasteners.

If you do put the cams in position with valves closed , you will need to support and hold the cam chain up while turning crank into proper position so the chain does not get bunched up down at the crank sprocket and damage the case. Yes that is more difficult than turning the crank into position and just undoing the cam cap ....and yes, if you don't hold the cam chain up there is risk of case damage, but I believe its less risk over all and easily mitigated vice removing the cam journal caps under load.

Marquez Motorcycle Services

Solutions to recurring maintenance

Race/Adventure ride event prep

Post event services

Total Rider

Your path to a TX motorcycle license

And advanced Rider training

Solutions to recurring maintenance

Race/Adventure ride event prep

Post event services

Total Rider

Your path to a TX motorcycle license

And advanced Rider training

Re: Valve Clearance ?

Thanks for all the input guys, really appreciate it!

Quick update: Rear cylinder is now properly adjusted and valve clearance measured:

RIL 0.13

RIR 0.13

REL 0.31

RER 0.32

Now back to the front and what do I see? Apparently off by a tooth (even though I adjusted it the last time), I can see the FE mark flush on cylinder head casing, GI is below it... does anyone remember the proper amount of chain links between the two markings?

Cheers,

Marc

Quick update: Rear cylinder is now properly adjusted and valve clearance measured:

RIL 0.13

RIR 0.13

REL 0.31

RER 0.32

Now back to the front and what do I see? Apparently off by a tooth (even though I adjusted it the last time), I can see the FE mark flush on cylinder head casing, GI is below it... does anyone remember the proper amount of chain links between the two markings?

Cheers,

Marc

- freeridenick

- Posts: 1660

- Joined: Fri May 23, 2014 1:30 pm

- Location: Derbyshire

Re: Valve Clearance ?

I'll be interested to see what response you get to those. The inlets seen tight and the exhausts are about right iirc.SadFool wrote: ↑Mon Mar 05, 2018 7:14 pm Thanks for all the input guys, really appreciate it!

Quick update: Rear cylinder is now properly adjusted and valve clearance measured:

RIL 0.13

RIR 0.13

REL 0.31

RER 0.32

Now back to the front and what do I see? Apparently off by a tooth (even though I adjusted it the last time), I can see the FE mark flush on cylinder head casing, GI is below it... does anyone remember the proper amount of chain links between the two markings?

Cheers,

Marc

What I'm most interested in is folks thoughts on the stock exhaust clearance. When I talked to my local engine builder he was surprised. Normally he'd expect around 0.2mm inlet and 0.25mm exhaust.

-

Roger Ditchfield

- Posts: 181

- Joined: Tue Apr 26, 2011 6:55 pm

Re: Valve Clearance ?

OEM CAMSHAFTS

INLET = 0.17mm +/- 0.03mm

EXHAUST = 0.30mm +/- 0.03mm

RE-PROFILED AND MORIWAKI ST1 CAMSHAFTS

INLET = 0.20mm +/- 0.03mm

EXHAUST = 0.30mm +/- 0.03mm

ST2 CAMSHAFTS

INLET = 0.20mm + 0.04mm

EXHAUST = 0.30mm + 0.04mm

INLET = 0.17mm +/- 0.03mm

EXHAUST = 0.30mm +/- 0.03mm

RE-PROFILED AND MORIWAKI ST1 CAMSHAFTS

INLET = 0.20mm +/- 0.03mm

EXHAUST = 0.30mm +/- 0.03mm

ST2 CAMSHAFTS

INLET = 0.20mm + 0.04mm

EXHAUST = 0.30mm + 0.04mm

-

Roger Ditchfield

- Posts: 181

- Joined: Tue Apr 26, 2011 6:55 pm

Re: Valve Clearance ?

VTR CAM TIMING PROCEDURE

WITH BOTH FRONT CYLINDER AND REAR CYLINDER CAMSHSHAFTS REMOVED (Starting from scratch)

1) Turn C/shaft until FT appears and lines up with the mark on the cover

2) Fit FRONT CYLINDER Exhaust camshaft with the mark FE on the exhaust camwheel level with the c/head and at the front of the bike.

3) Fit FRONT CYLINDER Inlet camshaft with the mark FI on the camwheel Level with the C/head and to the rear of the bik.

THE CAM LOBES WILL NOW BE POINTING AWAY FROM EACH OTHER

FIT CAM CAPS. Torque to 23nm in two stages

4) TURN THE C/SHAFT ANTI CLOCKWISE 270 DEGREES until RT appears and lines up

5) Fit the REAR CYLINDER Inlet cam with the mark RI on the camwheel level with the c/head and pointing to the front of the bike.

6) Fit REAR CYLINDER Exhaust Camshaft with the mark RE on the camwheel level with the c/head and at the rear of the bike.

THE CAM LOBES WILL NOW BE POINTING TOWARDS EACH OTHER

FIT CAM CAPS. Torque to 23nm in two stages

WITH BOTH FRONT CYLINDER AND REAR CYLINDER CAMSHSHAFTS REMOVED (Starting from scratch)

1) Turn C/shaft until FT appears and lines up with the mark on the cover

2) Fit FRONT CYLINDER Exhaust camshaft with the mark FE on the exhaust camwheel level with the c/head and at the front of the bike.

3) Fit FRONT CYLINDER Inlet camshaft with the mark FI on the camwheel Level with the C/head and to the rear of the bik.

THE CAM LOBES WILL NOW BE POINTING AWAY FROM EACH OTHER

FIT CAM CAPS. Torque to 23nm in two stages

4) TURN THE C/SHAFT ANTI CLOCKWISE 270 DEGREES until RT appears and lines up

5) Fit the REAR CYLINDER Inlet cam with the mark RI on the camwheel level with the c/head and pointing to the front of the bike.

6) Fit REAR CYLINDER Exhaust Camshaft with the mark RE on the camwheel level with the c/head and at the rear of the bike.

THE CAM LOBES WILL NOW BE POINTING TOWARDS EACH OTHER

FIT CAM CAPS. Torque to 23nm in two stages

Re: Valve Clearance ?

EX is supposed to be .27-.33mm so yours are in specSadFool wrote: ↑Mon Mar 05, 2018 7:14 pm Thanks for all the input guys, really appreciate it!

Quick update: Rear cylinder is now properly adjusted and valve clearance measured:

RIL 0.13

RIR 0.13

REL 0.31

RER 0.32

Now back to the front and what do I see? Apparently off by a tooth (even though I adjusted it the last time), I can see the FE mark flush on cylinder head casing, GI is below it... does anyone remember the proper amount of chain links between the two markings?

Cheers,

Marc

IN .14-.20mm So your Intake valves are too tight. As they wear they get tighter. As the engine heats up they get tighter.

At the min spec means valve is open more, good for performance.

Below the min spec and the valve may not be closing all the way, bad for performance and really bad for wear...the valve is partially cooled though heat transfer to the seat.. less contact , less cooling

Marquez Motorcycle Services

Solutions to recurring maintenance

Race/Adventure ride event prep

Post event services

Total Rider

Your path to a TX motorcycle license

And advanced Rider training

Solutions to recurring maintenance

Race/Adventure ride event prep

Post event services

Total Rider

Your path to a TX motorcycle license

And advanced Rider training