Here goes, I did this a few months back but was reluctant to mention it just in case it was a bad decision & caused me running issues. Now done, I can report no ill effects what so ever & have since covered around 400 miles on the engine.

Firstly I made sure the pistons were at tdc & the intake valves were closed then tightly packed around the valves with bog tissue, imagine loading an old musket. Making sure there was no way of touching the valve stem with sand paper.

It took me quite a few sheets of (coarsest I had) 180 grit 6" sticky da sander discs folded & torn into 3/4" strips & hours per head fingering the ports till I couldn't feel my finger

Once I was happy I pulled out the tissue using a bent welding rod as a hook, then blasted it clean with an air line

Here is what they used to look like.

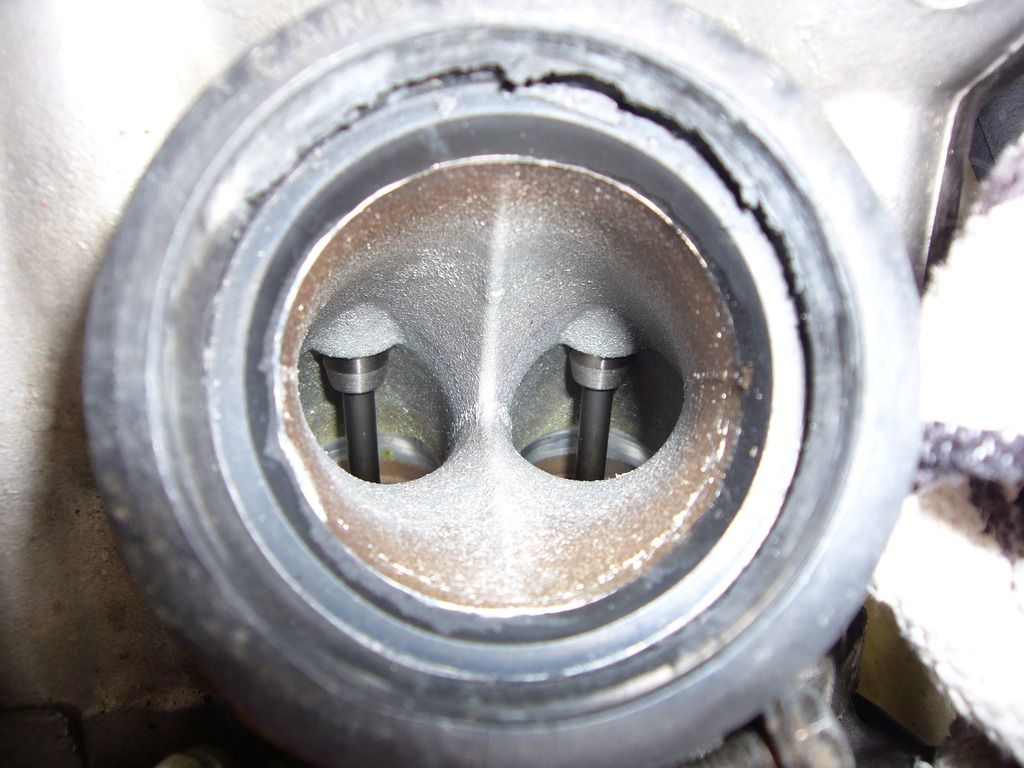

This is how they are now.

I have to buy a straight die grinder to knife edge the divider, as the 90°one will not reach with the short cartridge roll mandrel I have.

Not sure if there are any gains to be had by doing this & because so many changes have been done over the last few months its hard to tell what's improved what.

I know they still look a little rough around the most important part, the neck under the valve seat. But hey, the main chambers are as smooth as silk & with no running issues at all