I have read lots of those charts & the answer seems to be that Honda don't want us to know what needles they use. So we can correct their poor needle choice.

I thought this is a good read

http://davestestsandarticles.weebly.com ... jetage.pdf

The best advice "modifying solution" seems to come from motor cross & jet ski forums. They recon that if the needle is mostly good & you can identify the troublesome (lean) throttle area, just file a very small flat (works fine and more accurate) than sanding the circumference.

I do feel the DJ needles are very good with the clip in the second groove down from the blunt end, the dyno proves it & my ass.

From what I have read, it seems that it's the straight section that is too large a diameter & making that fuel zone too lean.

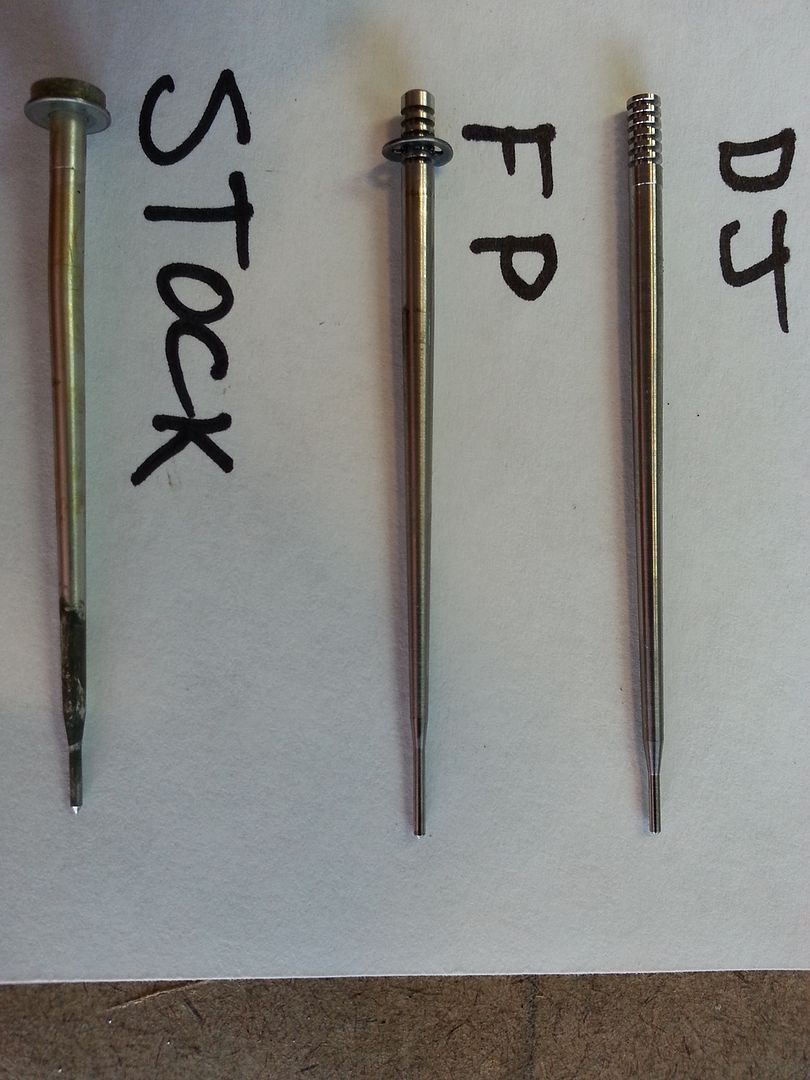

So here are my choices,

1, Remove the DJ needles & with a micrometer carefully file a flat on each "straight" section of the needle, if I mess it up slightly put the biggest flat (richer needle) in the rear to aid cooling

2, Remove the DJ needles & place the groove section in a drill, then carefully apply electrical tape to the section I don't want to touch. Then use wet & dry on each needle checking constantly the diameter micrometer until you get the desired diameter.

3, Measure up the DJ needles & cross reference the dimensions to a Keihin needle so we can all have access to a needle that can eliminate any rich or lean areas for ever.

Number 3 is the one I am gunning for & this is what I think so far, please correct me if I am wrong

The needle type is

N427-48, & they are all 66mm long. Std A1UC needles are 59.8mm top to bottom, so at a guess the extra length is to accommodate the grooves at the top for different clip heights 5x @ 0.9mm increments.

I also think that the "

A" in A1UC designates the taper of 1°, as there seems to be only one main taper apart from the tip. Which is there for safety reasons, to stop the needle coming out the needle jet hole & jamming the slide wide open.

I also think the U in A1UC designates the diameter of the "straight" section which is 2.785mm. Which would tally with the chart from Allens performance

http://www.allensperformance.co.uk/data-n427-48.html.

But my micrometer reads 2.810mm on the "straight" section, which = X or W on the Allens chart??

Then I've tried to work out the"L1" length in the Allens chart, by measuring how far the 2.515mm needle diameter was down from the under the "top hat" of the Std needle which is 19.52mm.

Then, to try & make some sense of the figures add 5 different (imaginary) clip grooves to the Std needle @ 0.9mm each = 4.5mm.

So we have 19.52mm + 4.5mm = 24.02mm. Which does not tally with any "L1" lengths, the shortest "L1" seems to be 34.55.

So then this is where my guess work ends, until I get the DJ needles out & measure them up.