Mega thanks for the pictures CruxGNZ

Deciphering the Keihin needle code.

Re: Deciphering the Keihin needle code.

I've been looking at your needle pictures (excellent btw) & I recon I would be going leaner again if I fitted the Factory Pro needles. They're so thin at the tip  .

.

Mega thanks for the pictures CruxGNZ Big help

Big help

Mega thanks for the pictures CruxGNZ

Re: Deciphering the Keihin needle code.

No problem about the pictures. Sorry about the quality of the stock needle. It was all I had and it is slightly bent and tarnished. I picked up a new micrometer tonight.

The measurements you asked for the Factory Pro needle:

Total: 63.04mm

L1: 17.02mm

Now, the "D" measurement I cant really give you. There is a taper from the bottom (looking at the picture you posted) of L1 all the way to the first clip position. That taper starts at 2.83mm and just under the first clip position is 2.86mm.

The measurements you asked for the Factory Pro needle:

Total: 63.04mm

L1: 17.02mm

Now, the "D" measurement I cant really give you. There is a taper from the bottom (looking at the picture you posted) of L1 all the way to the first clip position. That taper starts at 2.83mm and just under the first clip position is 2.86mm.

Re: Deciphering the Keihin needle code.

Big thanks for measuring up CruxGNZ, your a starThe measurements you asked for the Factory Pro needle:Total: 63.04mmL1: 17.02mmNow, the "D" measurement I cant really give you. There is a taper from the bottom (looking at the picture you posted) of L1 all the way to the first clip position. That taper starts at 2.83mm and just under the first clip position is 2.86mm.

Re: Deciphering the Keihin needle code.

TBH I am not sure that is even possible. Yeh there is room for some experimentation and you could re-profile one and it may then have an affect in another area which basically pushes the problem along possibly.I do feel confident that I could get the jetting sorted by cutting my own needle profile.

Saying that though, I really do admire your persistence. Your basically going on your own R&D on a cheaper budget with less precision tools/machinery. I'm not saying it's not possible as how did they make these things before the days of CAD and diagnostic equipment, so it must be possible. Really interesting though to compare the differences between needles. Don't forget that Dynojet needles are designed to work in conjunction with Dynojet mains which are measured by flow rate and are tapered unlike the Keihin/FP which are the same. This is one of the reasons I went the FP route. Dynojet also have the extra slide hole so I'm not sure comparing a FP needle against a Dynojet will work. Who knows....I may be wrong and like I say it's interesting to make comparisons.

How about the Sigma jet kit needles. Could be worth experimenting with as the kits are one of the cheapest around. http://www.vtr1000.org/phpBB3/viewtopic ... ilit=sigma

Have I just complicated things

Thanks for posting the pics CruxGNZ.

Vara I shall whip the carbs off at the weekend (chance for a bit of tinkering myself) and take some pics of FP needles and do my best to make some.....well, as accurate as I can (considering the taper) measurements with a Micrometer. Mmm How does one get the angle of the taper

(:-})

==============================Enter the Darkside

Re: Deciphering the Keihin needle code.

“Nothing in the world can take the place of persistence.cybercarl wrote:Saying that though, I really do admire your persistence.

Talent will not; nothing is more common than unsuccessful men with talent.

Genius will not; unrewarded genius is almost a proverb.

Education will not; the world is full of educated derelicts.

Persistence and determination alone are omnipotent.

The slogan Press On! has solved and always will solve the problems of the human race.”

― Calvin Coolidge

I was going to throw "VTR carburettor's" in there instead of "human race", but thought it a bit rude

Really appreciate it Carlcybercarl wrote:Vara I shall whip the carbs off at the weekend

I think I have had a positive result filing the needles Carl.

I haven't posted on this thread, it's on the "VTR cam" thread.

Re: Deciphering the Keihin needle code.

As requested....Has anyone access to Factory Pro needles?

Just thought I would ask, it any one has would they be kind enough to measure them up?

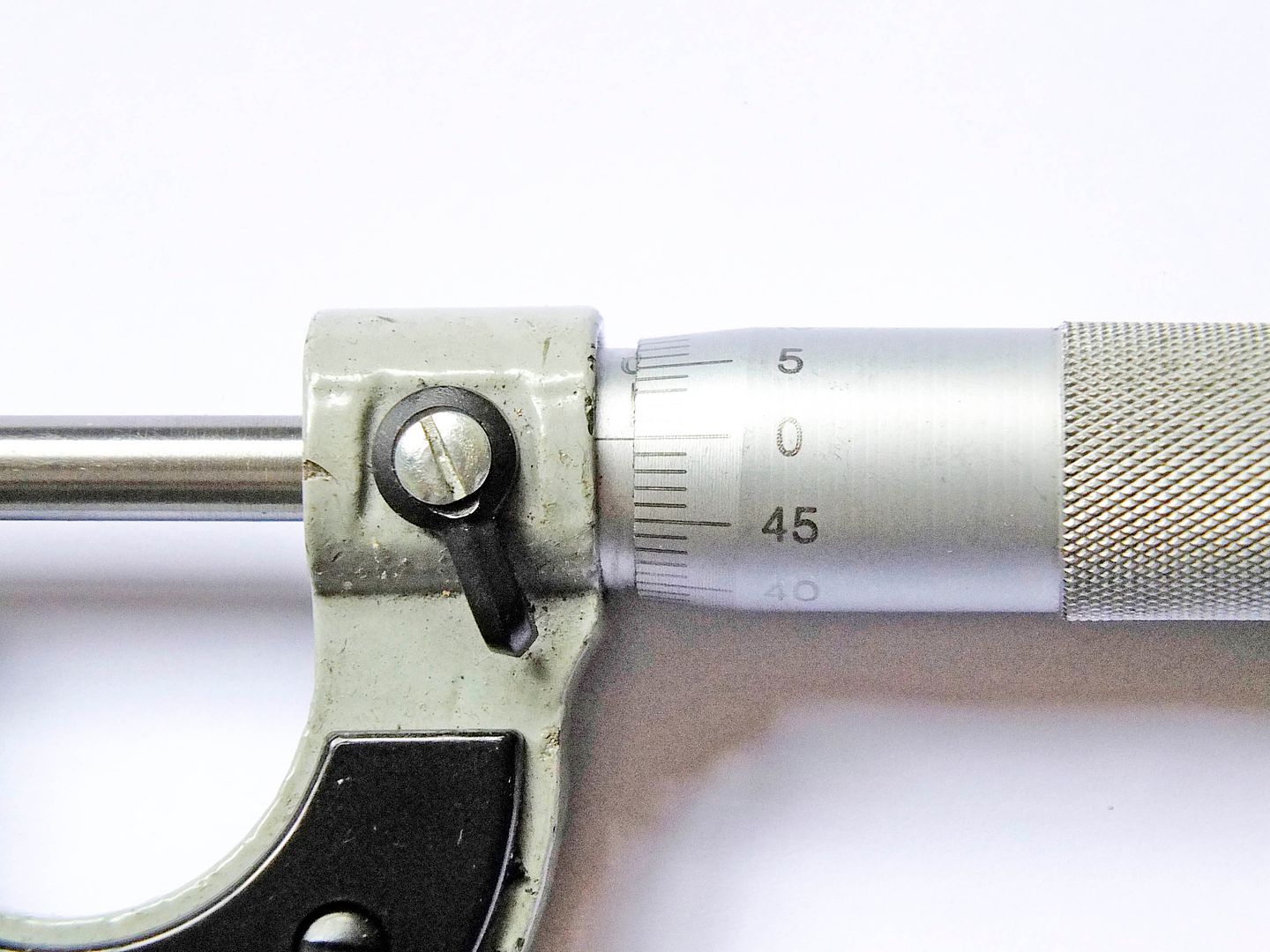

I started with calibrating my micrometer to zero. I basically set it to hand tighten lightly and then add two clicks on the clicker which gets me to zero.

My micrometer is not the best but I have measured as accurately as I could considering the taper and it's bloody fiddly trying to hold a needle in the micrometer and photograph it at the same time.

Micrometer is in 0.25mm increments.

Here we go then....

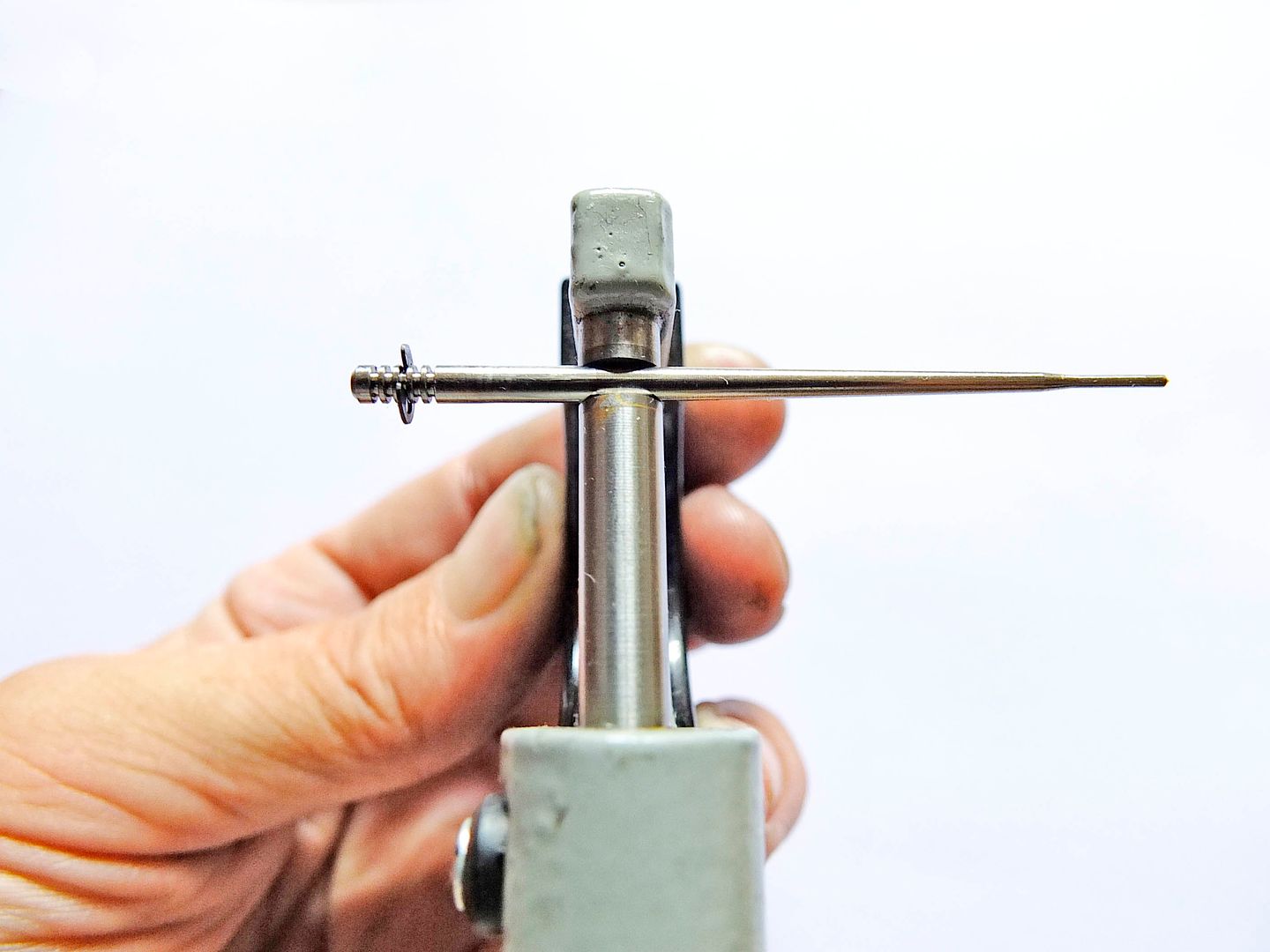

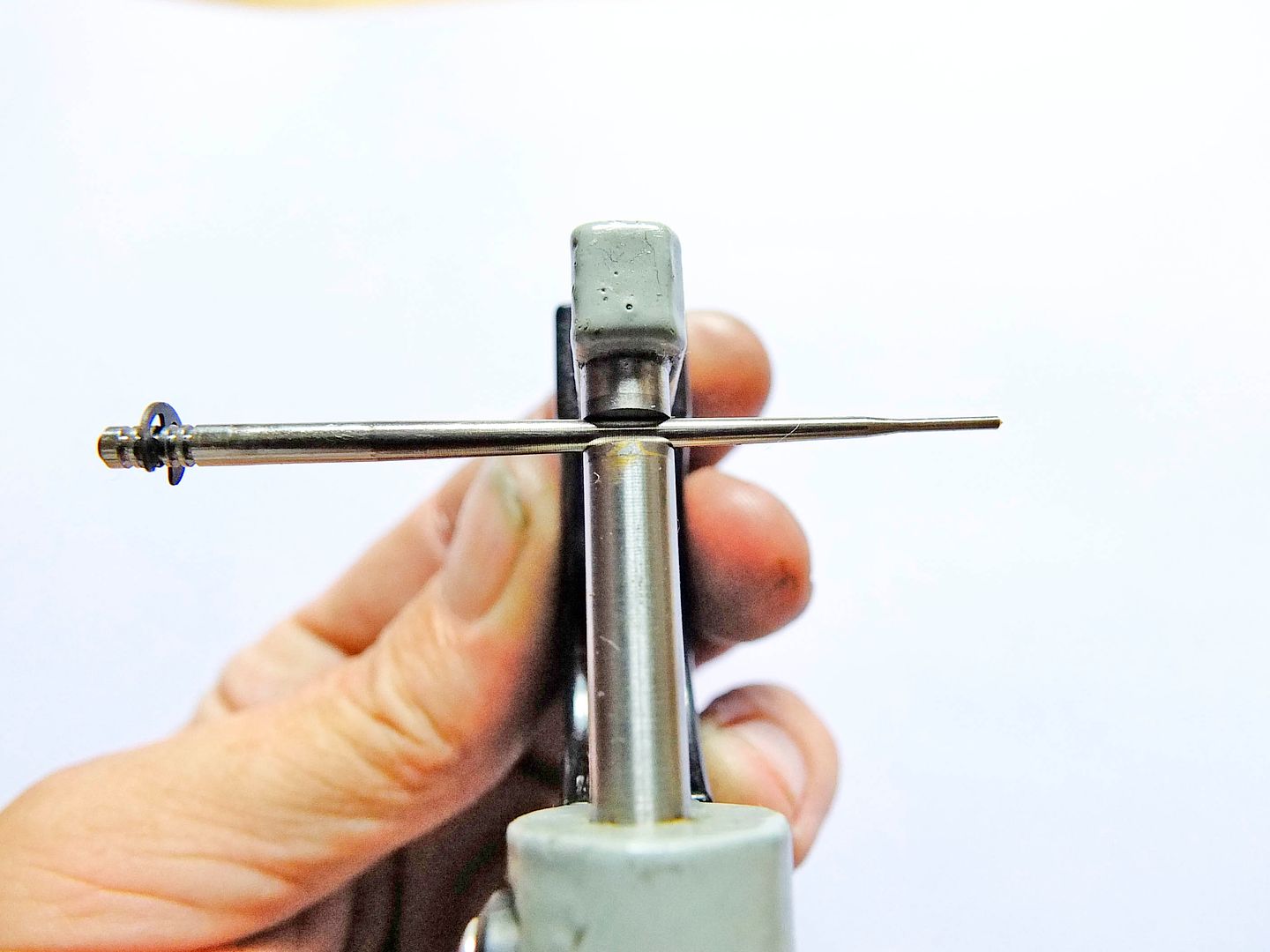

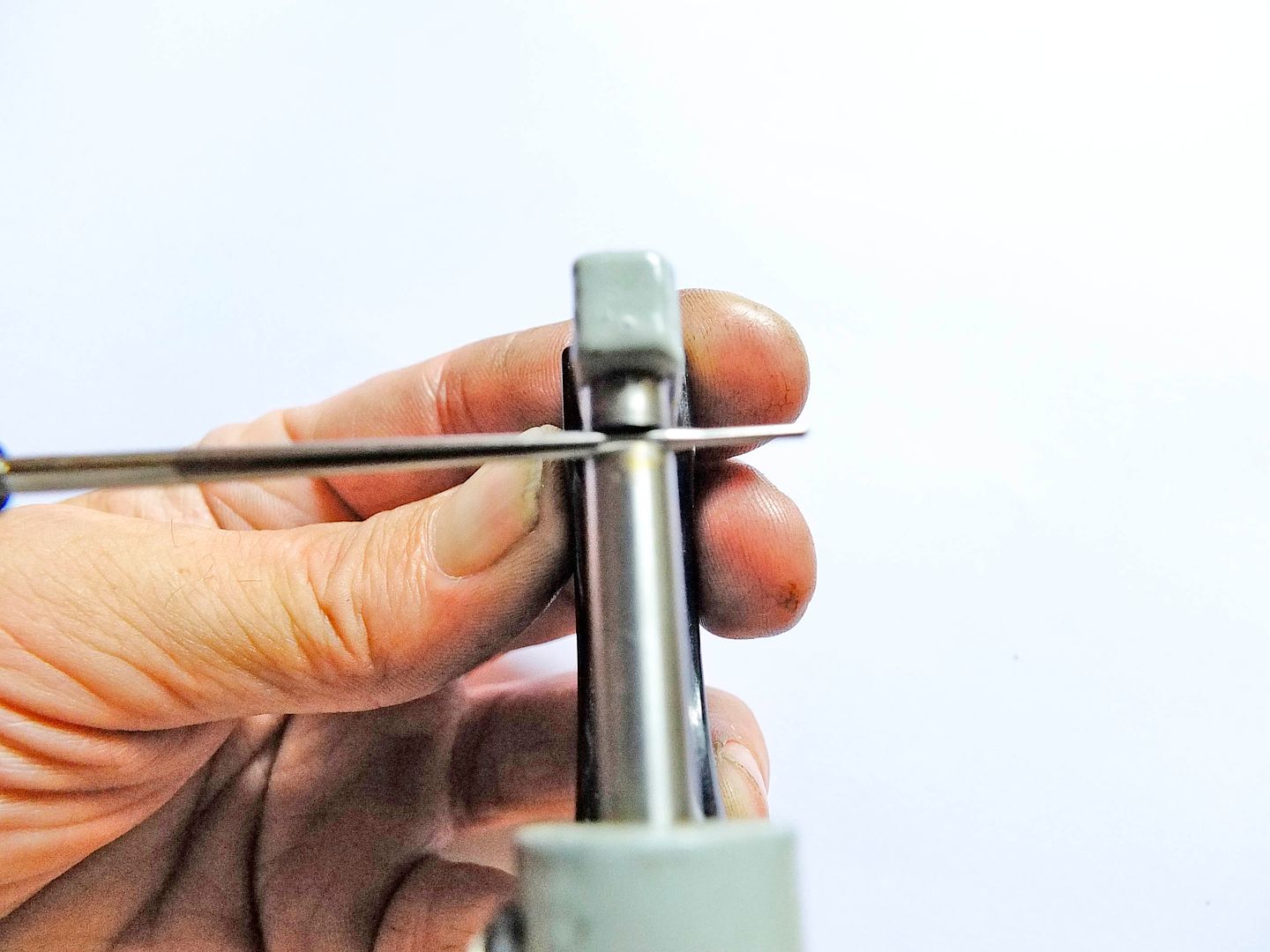

First the very top before the clip slots

Next is the top just before the taper starts

Then the middle of the taper. You can also see the wear mark where I took the last measurement.

Then the top of the tip right before is tapers off again into the tip.

Then the tip right below the taper

The length of the needle would not fit in my micrometer as it's only a small one so I used a Vernier gauge to measure this. A good job it has a measurement scale on it too as the battery is flat for the digital display.

Note that the Factory pro needles only have the 5 clip positions to choose from compared to dynojet which have 6.

Apologies for the badly lit pics.

Hope that helps.

(:-})

==============================Enter the Darkside

Re: Deciphering the Keihin needle code.

Firstly, Mega thanks Carl for taking the time to do this.

Right, this should be done with all three needles measured by one person, using the same measuring apparatus. But it isn’t going to happen unless some one has all the needles & has the enthusiasm to do it.

I have saved Carls pictures on my pc & decreased the sizes so they are similar in size to the real thing. Then transferred Carls distance down the needle measurements as best I can & compared them to the needles I have.

Its not 100% accurate, but is the best I can do at the moment

Straight section

Carls FP straight section------ 2.89mm

Std Needle straight section-- 2.85mm

Dyno Jet straight section----- 2.84mm

Middle section

Carls FP middle section------ 2.285mm

Std Needle middle section-- 2.30mm

Dyno Jet middle section----- 2.30mm

Prior to bottom taper section

Carls Prior to bottom taper section---------- 1.75mm

Std Needle Prior to bottom taper section-- 1.90mm

Dyno Jet Prior to bottom taper section----- 1.80mm

The tips are all 1mm in diameter, but I read that these are for safety & are there so the needle cannot leave the needle jet & jam the slide in a WOT situation.

I would say they are quite similar in the straight section area, but the FPro needles go thinner than both Std & DJ needles.

Perhaps making the 5000rpm-7000rpm richer again until you move onto the Main jet fuelling zone?

Have you tried lowering the needles so the clip is in the top groove? Just to see what's what in the 5000rpm-7000rpm zone?

I think you might be in for a surprise If its crappy, just put it back

If its crappy, just put it back  But if you like it like I did.............

But if you like it like I did.............

Cheers again Carl, top man

Right, this should be done with all three needles measured by one person, using the same measuring apparatus. But it isn’t going to happen unless some one has all the needles & has the enthusiasm to do it.

I have saved Carls pictures on my pc & decreased the sizes so they are similar in size to the real thing. Then transferred Carls distance down the needle measurements as best I can & compared them to the needles I have.

Its not 100% accurate, but is the best I can do at the moment

Straight section

Carls FP straight section------ 2.89mm

Std Needle straight section-- 2.85mm

Dyno Jet straight section----- 2.84mm

Middle section

Carls FP middle section------ 2.285mm

Std Needle middle section-- 2.30mm

Dyno Jet middle section----- 2.30mm

Prior to bottom taper section

Carls Prior to bottom taper section---------- 1.75mm

Std Needle Prior to bottom taper section-- 1.90mm

Dyno Jet Prior to bottom taper section----- 1.80mm

The tips are all 1mm in diameter, but I read that these are for safety & are there so the needle cannot leave the needle jet & jam the slide in a WOT situation.

I would say they are quite similar in the straight section area, but the FPro needles go thinner than both Std & DJ needles.

Perhaps making the 5000rpm-7000rpm richer again until you move onto the Main jet fuelling zone?

Have you tried lowering the needles so the clip is in the top groove? Just to see what's what in the 5000rpm-7000rpm zone?

I think you might be in for a surprise

Cheers again Carl, top man

Re: Deciphering the Keihin needle code.

There might be an elephant in the room, gents.

Fuel flows through the needle jet, in the gap between the needle itself and the hole in the needle jet.

But looking at the needle jet; which is integral with the carb body as far as I can tell, and therefore not replaceable, the hole will gradually wear oval.

The worse it gets, the less accurate fuel metering is. It will go richer the older the carb bodies are.

Does anyone know how to extract the needle jets and fit new ones?

Fuel flows through the needle jet, in the gap between the needle itself and the hole in the needle jet.

But looking at the needle jet; which is integral with the carb body as far as I can tell, and therefore not replaceable, the hole will gradually wear oval.

The worse it gets, the less accurate fuel metering is. It will go richer the older the carb bodies are.

Does anyone know how to extract the needle jets and fit new ones?

It's not falling off, it's an upgrade opportunity.

Re: Deciphering the Keihin needle code.

I know no one wants to hear what I have to say but you guys do not have the equipment required to measure the needles.

First you should look up what needs to be done to check a taper with the accuracy needed for this project.

Talk with a machinist and see what they would want to get the measurements on that chart, if you can find one willing to do it will be the only way to get the specs you need.

First you should look up what needs to be done to check a taper with the accuracy needed for this project.

Talk with a machinist and see what they would want to get the measurements on that chart, if you can find one willing to do it will be the only way to get the specs you need.

Loud pipes don't save lives, knowing how to ride your bike will save your life.

Re: Deciphering the Keihin needle code.

Yup, I concur. Have had it a good few times.tony.mon wrote:There might be an elephant in the room, gents.

Fuel flows through the needle jet, in the gap between the needle itself and the hole in the needle jet.

But looking at the needle jet; which is integral with the carb body as far as I can tell, and therefore not replaceable, the hole will gradually wear oval.

The worse it gets, the less accurate fuel metering is. It will go richer the older the carb bodies are.

Does anyone know how to extract the needle jets and fit new ones?

Re: Deciphering the Keihin needle code.

E.Marquez done his.Does anyone know how to extract the needle jets and fit new ones?

As I have said previously:The needle guide is pulled out with a slide hammer and pressed in with a guide rod machined fit to the ID.

http://www.superhawkforum.com/forums/te ... post351472

http://www.vtr1000.org/phpBB3/viewtopic ... 15#p386815If you think about all the R&D work gone into the design of the profile including CAD work and then precision cutting where a fraction of a mm can make huge differences with a tapered cut to add to the complications so it's not just the width at a chosen point but the angle of the taper.

So I am also in agreement that this is in no way an accurate representation and should not be taken as is. But as requested I have taken what I would consider to be rough measurements. It may show some differences between the various needles but as has been mentioned for more accuracy on this it should be done by the same person, same measurement device with all 3 needles, preferably on the same day. A bit like comparing bikes on a dyno

On a side note does anyone know of a home measuring device like a micrometer or vernier that measures tapers/angles accurately. I'm thinking it would have to be a clever device that can make calculations from one end to the other end of the taper to give a reading. I could be wrong but I'm curious. I have no idea... how one measures a taper. Maths

IMO this is only of any use out of curiosity and experimentation. This is one small section of the carbs and because one thing affects another they need to be worked on as a whole, if you know what I mean. What I am trying to say is, for example, that if you changed out the diaphragm springs for new genuine worn-out springs, this then has an affect on the slides. Changing the springs does make a big difference. The springs do shrink and loose they tension over the years and one carb may be more worn than the other so the slides work unevenly. Yes I know the stacks will make a difference here but it's also the tension giving a smoother, more snappier slide action.

The same with the needle jets. Change these out, then this has an affect on the needle height required according to how much fuel they let through. And while on this subject. It should be noted that with the FP Ti needles, they could wear out the needle jets faster than a softer metal. So don't think one could swap parts from one carb to another without differences. Another reason why they all require a slightly different set-up.

Float needle valves is another one. Replace these as they get worn and sit lower in the seat which affects the float height. We are only talking a fraction of a mm here sometimes but it can make a difference. It's funny how the smaller parts get missed, but you change all these for unworn parts and it has an accumulative affect on the carbs and tuning as a whole.

Am I waffling

I shall end this post with......

Every Action has an Equal and Opposite Reaction?

(:-})

==============================Enter the Darkside

Re: Deciphering the Keihin needle code.

'' I have no idea... how one measures a taper. Maths  Not my strong point.''

Not my strong point.''

With a Tapermeasure...

With a Tapermeasure...

Making up since 2007, sometimes it's true...Honest...

Re: Deciphering the Keihin needle code.

Boom BoomMacV2 wrote:With a Tapermeasure...

Re: Deciphering the Keihin needle code.

Sine Plate.

Should set you back around $500 us for that bit and it is just to set the part on.

Then you need the blocks and measuring tools, so it gets real expensive, real quick

Should set you back around $500 us for that bit and it is just to set the part on.

Then you need the blocks and measuring tools, so it gets real expensive, real quick

Loud pipes don't save lives, knowing how to ride your bike will save your life.

Re: Deciphering the Keihin needle code.

We should ask Jackflash if he can turn some needle jets up.