Well you asked for another Ducati build

Re: Well you asked for another Ducati build

A few more and it's an indoor swimming pool

It's not falling off, it's an upgrade opportunity.

Re: Well you asked for another Ducati build

its a car hoistfreeridenick wrote: ↑Fri Nov 13, 2020 6:55 pm I think I've said this before but I've got some serious garage envy and now you show TWO sunken hydraulic bike lifts.

At the side of the garage is my workshop... and up the stairs is a large storage loft... but I never talk about what's up there incase my wife reads this

The stripdown continues… so far just one slight hitch… a broken bolt in the swinging arm… soon drilled and tapped out though... I bought a set of cobalt drills last year, they are brilliant for this sort of thing. wish I had bought them years ago!

Re: Well you asked for another Ducati build

Looking good. Love all your kit. Tbh most of it would be wasted on me, but you can make it perform !!

Re: Well you asked for another Ducati build

Tried to remove the cush rubbers today as I am going to have the wheels powder coated... the rubbers were good, so I didn't want to destroy them. You can't knock them out as the drift just bounces off the rubber, and there is no way to get to the outer sleeve... So I made this puller, that has a split threaded cotter. its a bit fiddly, but they came out a treat, and I can re use them now

Re: Well you asked for another Ducati build

Did you warm up the wheel as well?

That should help.

That should help.

It's not falling off, it's an upgrade opportunity.

Re: Well you asked for another Ducati build

Good work with the puller you madebuzzer wrote: ↑Sun Nov 15, 2020 4:22 pm Tried to remove the cush rubbers today as I am going to have the wheels powder coated... the rubbers were good, so I didn't want to destroy them. You can't knock them out as the drift just bounces off the rubber, and there is no way to get to the outer sleeve... So I made this puller, that has a split threaded cotter. its a bit fiddly, but they came out a treat, and I can re use them now

Chris.

Re: Well you asked for another Ducati build

Just preparing the frame and parts to take to the powder coaters... On the grab handle there were two small dents that I just know that if I left them they would bug me forever,  so I TIG brazed them up and filed them down. there is something really satisfying about TIG brazing!

so I TIG brazed them up and filed them down. there is something really satisfying about TIG brazing!

Re: Well you asked for another Ducati build

Looks like the engine has never been worked on, apart from someone has removed the alternator cover and put it back on with what could best be described as glue! normally they come off with a tap, but in this case I had to resort to a puller…

Re: Well you asked for another Ducati build

Fingers crossed the cover comes off in one piece

Chris.

Re: Well you asked for another Ducati build

the engine is all apart, and I am pleased with its condition... no bore wear, and everything look good. the main reason to take it apart is to bead blast the cases... which of course means a complete strip. I am glad I did it anyway as people on the ducati forums have pointed out the crank plugs come loose which damages the cases. While this one was not loose, it was not tight either can came out with a gentle twist of the screw driver... disaster waiting to happen! its locktited in place now...

I hate bashing bearings out,and where possible try to make a puller of some sort… in the case of the swinging arm bearings it’s easy, just a stepped bush (it does destroy the inner seal..) and out they come. the step needs to clear the circlip though… some of the engine bearings are more difficult as you can’t get to the back… for this I made an expandable stepped puller, that expands into the bearing as a bolt rides up an internal taper. with this they come out easy…

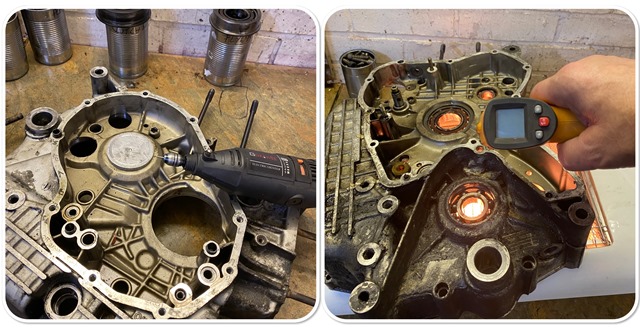

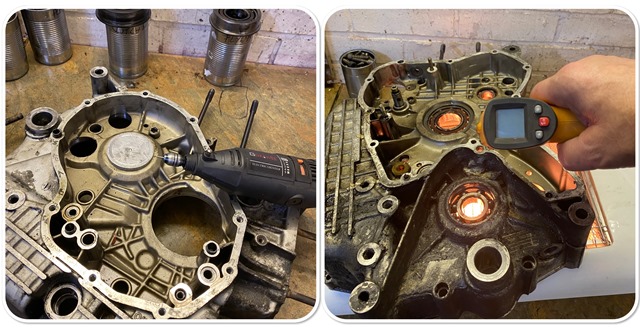

To get the bearings out I also heat the cases… I would like to use the oven as its a more even heat… but I can’t for two reasons.. the first is the cases are too big… and secondly she gets upset, particularly as its a new oven! So over the halogen heater it is… keeping an eye on the temperature… I also like to mark EVERYTHING, so it can go back where it came from, and in the same position. I am not keen on centre pops, instead I use a little diamond burr in the dremel… this will even mark bearings and means you can number stuff as well, and it does not cause stress raisers…

Of course parting the cases means the primary gear has to come off… and they are VERY tight… you can forget anything but a really robust puller. here is one I mad a few years ago. with this it came off easily.

The frame and wheels have gone to the powder coaters...

I hate bashing bearings out,and where possible try to make a puller of some sort… in the case of the swinging arm bearings it’s easy, just a stepped bush (it does destroy the inner seal..) and out they come. the step needs to clear the circlip though… some of the engine bearings are more difficult as you can’t get to the back… for this I made an expandable stepped puller, that expands into the bearing as a bolt rides up an internal taper. with this they come out easy…

To get the bearings out I also heat the cases… I would like to use the oven as its a more even heat… but I can’t for two reasons.. the first is the cases are too big… and secondly she gets upset, particularly as its a new oven! So over the halogen heater it is… keeping an eye on the temperature… I also like to mark EVERYTHING, so it can go back where it came from, and in the same position. I am not keen on centre pops, instead I use a little diamond burr in the dremel… this will even mark bearings and means you can number stuff as well, and it does not cause stress raisers…

Of course parting the cases means the primary gear has to come off… and they are VERY tight… you can forget anything but a really robust puller. here is one I mad a few years ago. with this it came off easily.

The frame and wheels have gone to the powder coaters...

Re: Well you asked for another Ducati build

Good to see your progressbuzzer wrote: ↑Wed Nov 18, 2020 4:44 pm the engine is all apart, and I am pleased with its condition... no bore wear, and everything look good. the main reason to take it apart is to bead blast the cases... which of course means a complete strip. I am glad I did it anyway as people on the ducati forums have pointed out the crank plugs come loose which damages the cases. While this one was not loose, it was not tight either can came out with a gentle twist of the screw driver... disaster waiting to happen! its locktited in place now...

I love your homemade pullers

Where are these crank plugs you mention (main journal ends may be)

Chris.

Re: Well you asked for another Ducati build

I think that big headed screw IS the crank plug, and the hole is where it came from, Chris.

It's not falling off, it's an upgrade opportunity.

Re: Well you asked for another Ducati build

Spot on Chris!

Re: Well you asked for another Ducati build

Well I never, thanks guy's

Chris.

Chris.