Well you asked for another Ducati build

Re: Well you asked for another Ducati build

Whats the plan style wise for it? .

the older i get,the faster i was

Re: Well you asked for another Ducati build

its sort of evolving in my head, i need to get the sequence of the build right... I want to change the rim sizes to 17" front and back... which I need to do before I mount the tank and make the seat hoop, so I need the wheels rebuilding first... If you make the seat and tank with the wheels as they are, you end up with the stance wrong... I like to build with a spirit level so the tank and seat lines are horizontal.

So its off next week to chat to the wheel builder

So its off next week to chat to the wheel builder

Re: Well you asked for another Ducati build

I was wondering if you would be ditching the 19" front wheel, good manbuzzer wrote: ↑Sat Jan 06, 2024 6:14 pm its sort of evolving in my head, i need to get the sequence of the build right... I want to change the rim sizes to 17" front and back... which I need to do before I mount the tank and make the seat hoop, so I need the wheels rebuilding first... If you make the seat and tank with the wheels as they are, you end up with the stance wrong... I like to build with a spirit level so the tank and seat lines are horizontal.

So its off next week to chat to the wheel builder

Chris.

Re: Well you asked for another Ducati build

well te angle grinder came out....

I recently bought a new one, which is small, and importantly has a soft start, which I didn’t know i needed until I had it!

I like to have a design brief in my head before I start, In this case, as always it will be minimalist… As light as I can make it… Parts I do put back on I will ask myself, “can I make it?” The front wheel will be changed to a 17” to match the rear, which will entail a wheel building session, something I have wanted to do for years… we will see!

I recently bought a new one, which is small, and importantly has a soft start, which I didn’t know i needed until I had it!

I like to have a design brief in my head before I start, In this case, as always it will be minimalist… As light as I can make it… Parts I do put back on I will ask myself, “can I make it?” The front wheel will be changed to a 17” to match the rear, which will entail a wheel building session, something I have wanted to do for years… we will see!

Re: Well you asked for another Ducati build

Well that's sorted that out

Your wife obviously hasn't realised you're back in the garage

Chris.

Your wife obviously hasn't realised you're back in the garage

Chris.

- lloydie

- Posts: 20928

- Joined: Mon Jan 17, 2011 11:16 pm

- Location: In the garage somewhere in Coventry

Re: Well you asked for another Ducati build

Re: Well you asked for another Ducati build

If you're building your own wheel, I'd suggest you buy the rim pre-drilled to fit your hub size. Starting with a blank rim can be tricky when you can't see the angle each spoke needs to sit in the rim. And measure the offset (how far to the side the centreline of the rim sits compared to the centreline of the hub) before you take it apart.

Many years back I became frustrated that, every time I smashed a bike up, I could fix everything myself except the wheels- which I had to take to a wheel builder.

One day I saw an advert for a wheel builder from Hagon, looking for a wheel builder, in MotorCycle News.

I went to see Alf Hagon, who asked me how much experience I had. I said none at all, but it wound me up that I couldn't build wheels. I knew that they employed two wheel builders, so if they were looking for one they still had one left.

I made Alf an offer: if he took me on to train alongside the experienced man he could pay me what he thought I was worth, and I'd guarantee to stay for six months. After that, if we were both happy I'd stay, otherwise he had plenty of time to find an experienced man.

I must have been the only applicant, because he shook my hand and I started there a week later. They're still going, and sell the parts you'll need.

So I learnt how to build wheels- I've forgotten most of it now, because just after I started the first Comstar wheels came out, then cast, forged and now, carbon.

So the market for spoked wheels diminished quite a bit, but there was always a queue on Mondays from grasstrack sidecar owners especially. They destroyed a rear every meeting. The worst ones to do? E-type Jaguar wheels. They have thick but short spokes and a massive offset, and every time an owner tried to drive up a curb to park they'd go out of round, and the owner would bring them back complaining.

I have a 1973 Honda SL125 (technically it belongs to the wife because I bought it using the savings we had put aside for her engagement ring, so she insisted that the logbook went in her name) which I have been rebuilding on and off for years. It has only 7000 miles from new.

I rebuilt the wheels with new spokes, rims and tyres about 20 years ago but it was never finished, so the chromed rims rusted before they were even used- and the tyres were too old. I rebuilt them again three years back. I just about remembered how to true them!

Now I'm retired I will get that bike finished in the next couple of months.

Sorry about the thread hijack!

Many years back I became frustrated that, every time I smashed a bike up, I could fix everything myself except the wheels- which I had to take to a wheel builder.

One day I saw an advert for a wheel builder from Hagon, looking for a wheel builder, in MotorCycle News.

I went to see Alf Hagon, who asked me how much experience I had. I said none at all, but it wound me up that I couldn't build wheels. I knew that they employed two wheel builders, so if they were looking for one they still had one left.

I made Alf an offer: if he took me on to train alongside the experienced man he could pay me what he thought I was worth, and I'd guarantee to stay for six months. After that, if we were both happy I'd stay, otherwise he had plenty of time to find an experienced man.

I must have been the only applicant, because he shook my hand and I started there a week later. They're still going, and sell the parts you'll need.

So I learnt how to build wheels- I've forgotten most of it now, because just after I started the first Comstar wheels came out, then cast, forged and now, carbon.

So the market for spoked wheels diminished quite a bit, but there was always a queue on Mondays from grasstrack sidecar owners especially. They destroyed a rear every meeting. The worst ones to do? E-type Jaguar wheels. They have thick but short spokes and a massive offset, and every time an owner tried to drive up a curb to park they'd go out of round, and the owner would bring them back complaining.

I have a 1973 Honda SL125 (technically it belongs to the wife because I bought it using the savings we had put aside for her engagement ring, so she insisted that the logbook went in her name) which I have been rebuilding on and off for years. It has only 7000 miles from new.

I rebuilt the wheels with new spokes, rims and tyres about 20 years ago but it was never finished, so the chromed rims rusted before they were even used- and the tyres were too old. I rebuilt them again three years back. I just about remembered how to true them!

Now I'm retired I will get that bike finished in the next couple of months.

Sorry about the thread hijack!

It's not falling off, it's an upgrade opportunity.

Re: Well you asked for another Ducati build

Thats Interesting Tony! I have ordered the spokes today so I will see how i get on!

first job has been to fabricate the rear subframe. I bought a pre bent hoop off Ebay and some Rod Ends. Its quite difficult to get a nice bend like this without kinking or specialist equipment, but I was able to put a slight bend in there by heating with a Mapp gas torch. I did think about just welding it on, but I do like the industrial look of rod ends, and they make attachment point easy and adjustable. The bolts through the frame will be 8.8 high tensile and not stainless in this application. I will also be sleeving the frame where the bolts pass through and welding the bosses I have made on there.

first job has been to fabricate the rear subframe. I bought a pre bent hoop off Ebay and some Rod Ends. Its quite difficult to get a nice bend like this without kinking or specialist equipment, but I was able to put a slight bend in there by heating with a Mapp gas torch. I did think about just welding it on, but I do like the industrial look of rod ends, and they make attachment point easy and adjustable. The bolts through the frame will be 8.8 high tensile and not stainless in this application. I will also be sleeving the frame where the bolts pass through and welding the bosses I have made on there.

Re: Well you asked for another Ducati build

I also like the look of the rod-ends, plus you have some adjustment there as well

Chris.

Chris.

Re: Well you asked for another Ducati build

You make making a bike look as easy as making toast lol  . and i can burn toast

. and i can burn toast  .

.

carry on..

carry on..

the older i get,the faster i was

- Pete.L

- Forum Health And Safety Officer

- Posts: 7301

- Joined: Fri Sep 26, 2003 5:09 pm

- Location: Bristol

Re: Well you asked for another Ducati build

My new ride is a bit of a Howler and I love to make her Squeal

Re: Well you asked for another Ducati build

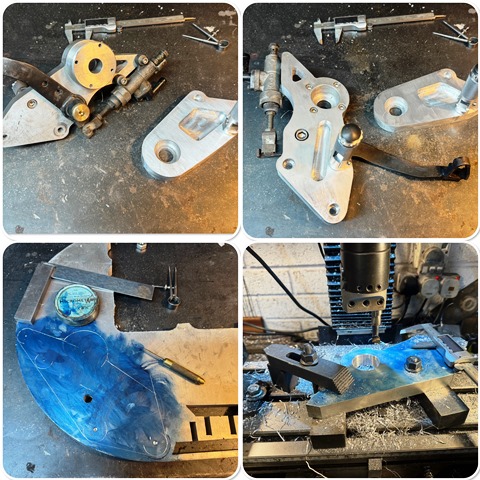

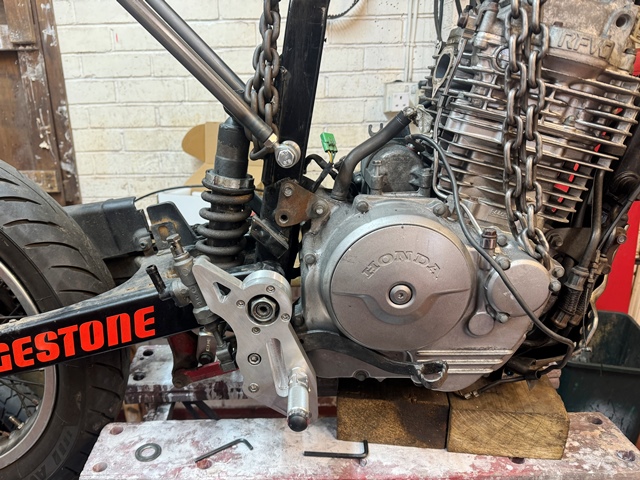

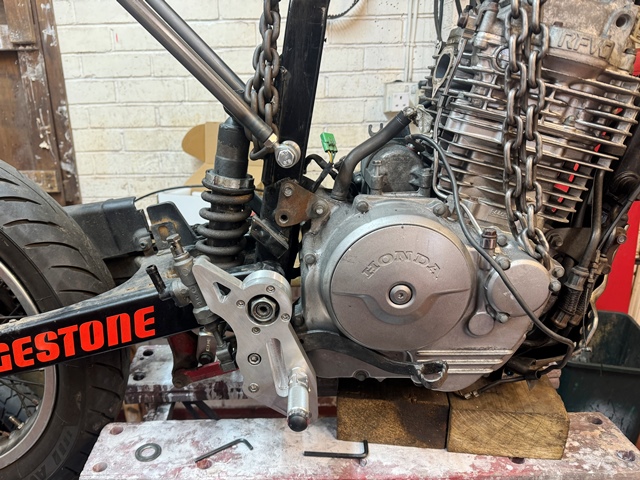

Next job took some thinking about and making… the footrest plates are structural to the frame as they support the ends of the swinging arm. I also wanted to move the pegs forward slightly… here is the result… more chunky than I usually make but they need to be!

Re: Well you asked for another Ducati build

I bet they did take some thinking about

They look so much better than the bulky originals

I have sent you a PM Tony

Chris.

They look so much better than the bulky originals

I have sent you a PM Tony

Chris.

Re: Well you asked for another Ducati build

Think i will stick to toast lol  . thats some serious metal work

. thats some serious metal work

the older i get,the faster i was

Re: Well you asked for another Ducati build

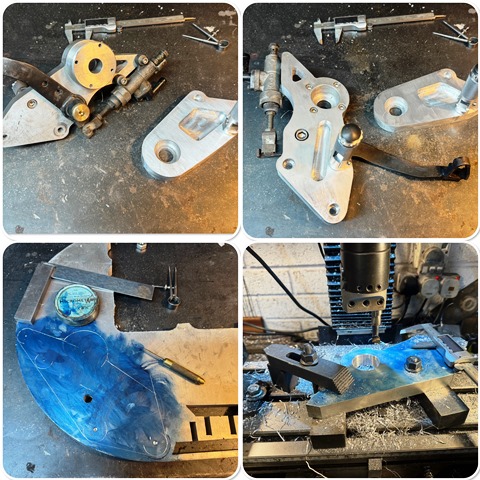

I bought a new Keihin 41mm FCR carb for the bike… while it actually fits on the original manifold I wanted it to stick out a little more, so I decided to make a longer and different manifold. I am still not sure which one to use, but now have the option.

That plate of aluminium is aircraft quality and mills really well... However, the milling chips are small and exceptionally sharp and I have received an official warning that I must shale my overalls off in the garage and remove my shoes before coming into the house :'(

That plate of aluminium is aircraft quality and mills really well... However, the milling chips are small and exceptionally sharp and I have received an official warning that I must shale my overalls off in the garage and remove my shoes before coming into the house :'(